Description

Packaging specification

20KG carton

Application

ABS, PC, PU, TPE elastomers

Contact Us Now!

If you need Price, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@changhongchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

| Low Impurity Phosphites | ||

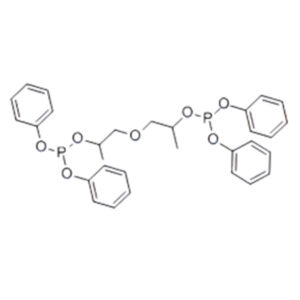

| CHLUMIAO® DPOP | CAS 15647-08-2 | 2-ethylhexyl diphenyl phosphite |

| CHLUMIAO® 8621 | CAS 68123-00-2 | Antioxidant 8621 |

| CHLUMIAO® DPDP | CAS 26544-23-0 | Antioxidant DPDP |

| CHLUMIAO® PDDP | CAS 25550-98-5 | Antioxidant PDDP |

| CHLUMIAO® PDOP | CAS 3164-60-1 | Antioxidant PDOP |

| CHLUMIAO® TPP | CAS 101-02-0 | Antioxidant TPP |

| CHLUMIAO® Poly(dicyclopentadiene-co-p-cresol) | CAS 68610-51-5 | Poly(dicyclopentadiene-co-p-cresol) |

| CHLUMIAO® SEED | CAS 42774-15-2 | Antioxidant SEED / Omnistab LS 5519 / Light Stabilizer 856 |

| Inhibited phenolic Antioxidants | ||

| CHLUMIAO® 264 | CAS 128-37-0 | Antioxidant 264 / Butylated hydroxytoluene |

| CHLUMIAO® 2,6-Di-tert-butylphenol | CAS 128-39-2 | 2,6-Di-tert-butylphenol |

| CHLUMIAO® 300 | CAS 96-69-5 | Irganox 300 / Antioxidant 300 |

| CHLUMIAO® 2246 | CAS 119-47-1 | Irganox 2246 / BNX 2246 |

| CHLUMIAO® 1222 | CAS 976-56-7 | Antioxidant 1222 / Irganox 1222 |

| CHLUMIAO® 702 | CAS 118-82-1 | Irganox 702 / Antioxidant 702 / Ethanox 702 |

| CHLUMIAO® DBHQ | CAS 88-58-4 | Antioxidant DTBHQ |

| CHLUMIAO® MTBHQ | CAS 1948-33-0 | 2-tert-butylhydroquinone聽 Industrial Grade |

| CHLUMIAO® 1076 | CAS 2082-79-3 | Irganox 1076 / Antioxidant 1076 |

| CHLUMIAO® 1010 | CAS 6683-19-8 | Irganox 1010 / Antioxidant 1010 |

| CHLUMIAO® 1330 | CAS 1709-70-2 | Irganox 1330 / Ethanox 330 |

| CHLUMIAO® 1520 | CAS 110553-27-0 | Irganox 1520 / Antioxidant 1520 |

| Phenol Free Phosphites Antioxidants | ||

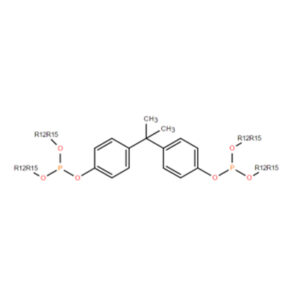

| CHLUMIAO® 8608 | CAS 26544-27-4 | Antioxidant AO DPD / Everaox 202 |

| CHLUMIAO® 430 | CAS 36788-39-3 | Antioxidant 430 / WESTON 430 |

| CHLUMIAO® 8608T | CAS 1334238-11-7, 69439-68-5 | Antioxidant 8608T |

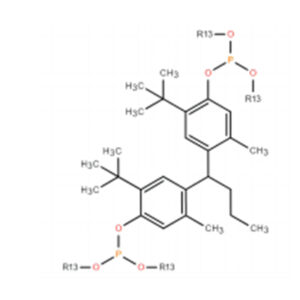

| CHLUMIAO® 8627 | CAS 68610-62-8 | Antioxidant 8627 |

| CHLUMIAO® TDP | CAS 25448-25-3 | Antioxidant TDP |

| CHLUMIAO® TLP | CAS 3076-63-9 | Antioxidant TLP |

| CHLUMIAO® TOP | CAS 301-13-3 | Antioxidant TOP |

| CHLUMIAO® TTDP | CAS 77745-66-5 | Antioxidant TTDP |

| Thiol esters Antioxidants | ||

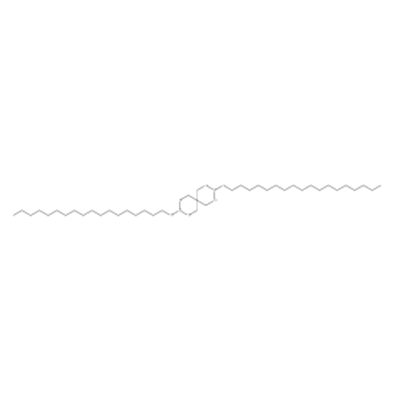

| CHLUMIAO® DLTDP | CAS 123-28-4 | Dilauryl thiodipropionate |

| CHLUMIAO® DSTDP | CAS 693-36-7 | istearyl thiodipropionate/ Antioxidant DSTDP |

| Aminic Antioxidants | ||

| CHLUMIAO® 3114 | CAS 27676-62-6 | Irganox 3114 / Antioxidant 3114 |

| CHLUMIAO® 4,4′-biphenol | CAS 92-88-6 |

4,4′-biphenol |

| Metal deactivators Antioxidants | ||

| CHLUMIAO® 1098 | CAS 23128-74-7 | Irganox 1098 / Antioxidant 1098 |