광개시제는 UV 경화 및 3D 프린팅을 어떻게 지원합니까?

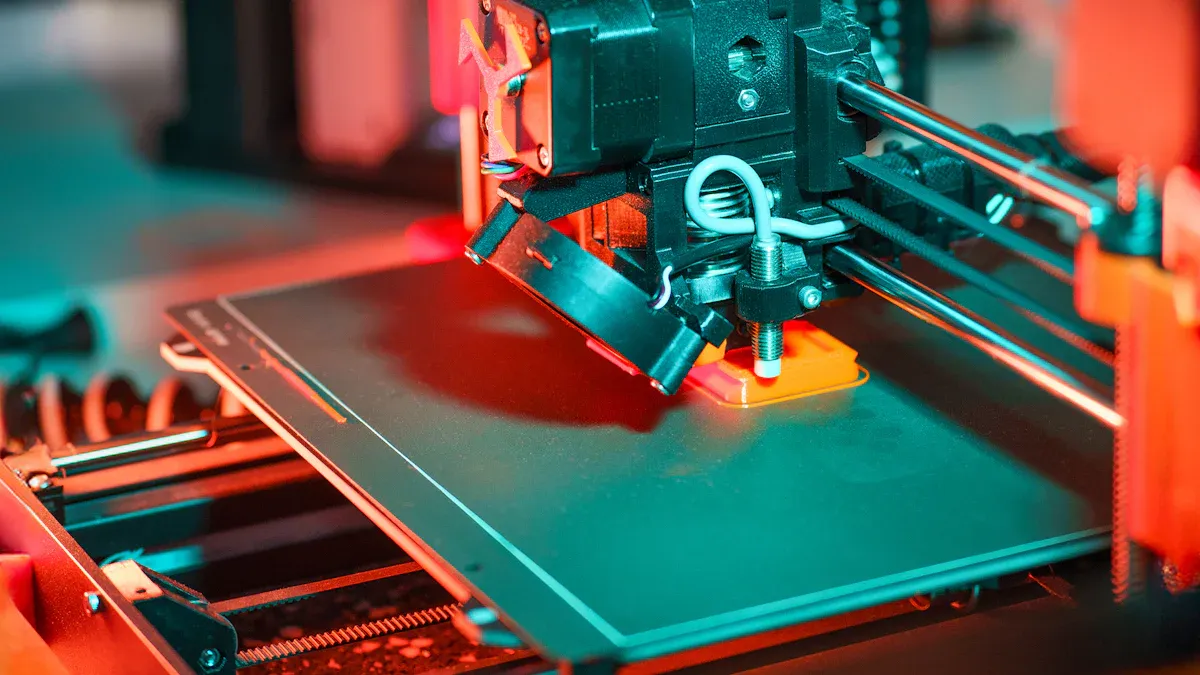

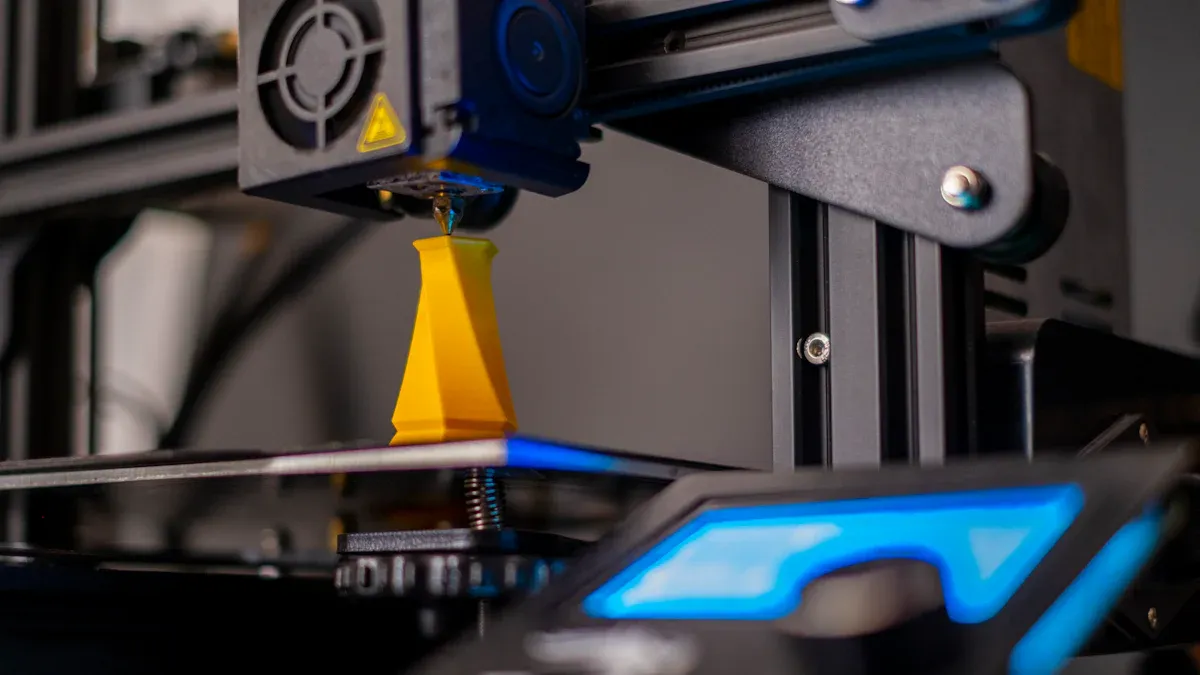

Photoinitiators start chemical reactions when ultraviolet light hits them. This makes materials harden fast in uv curing. It also helps make detailed objects in 3D printing. A photoinitiator takes in ultraviolet energy and begins polymerization. This process changes liquid into solid. Photoinitiators are very important in uv curing and 3D printing. They help make things quickly, accurately, and efficiently. Using photoinitiators gives many clear benefits:

| 기능 | Photocuring (DLP) | Traditional Methods |

|---|---|---|

| Speed | 100–1000 mm³/sec | 느린 |

| Precision | Up to 10 μm | Lower resolution |

| 기술 | Uses photoinitiators | Non-light-based |

| 애플리케이션 | Microtissue | General |

- Photoinitiators help save energy and cut production costs.

- The market for photoinitiators is growing very fast. It is now worth billions of dollars around the world.

주요 내용

- Photoinitiators are very important for UV curing and 3D printing. They help start chemical reactions. These reactions change liquids into solids very fast.

- Using photoinitiators helps save time and energy. This makes things get made faster in factories. It also helps factories work better.

- Picking the right photoinitiator is very important. It can change how good, fast, and detailed the final product is.

- There are different kinds of photoinitiators. Each kind works best with certain materials and light sources. Using the right match gives better results.

- New photoinitiator designs help lower problems like color change and toxicity. This makes products safer for use in medicine and food.

Photoinitiators and Their Role

What Is a Photoinitiator?

A photoinitiator is a special chemical. It starts a reaction when it gets light. Scientists use photoinitiators to turn liquids into solids. These chemicals react to light, mostly ultraviolet. They begin something called polymerization. Polymerization links small molecules together. This makes a solid structure. Photoinitiators are important in many industries. They help make strong coatings, adhesives, and medical devices.

Photoinitiators are like tiny switches. When light hits them, they turn on. They start the curing process. This makes them great for fast and careful manufacturing.

Essential Function in UV Curing and 3D Printing

Photoinitiators work in different ways in uv curing and 3D printing. In uv curing, the photoinitiator takes in uv light. This energy makes the chemical excited. It creates reactive species. These can be free radicals or cations. They start the curing process. The material gets hard fast and forms a solid layer. This method saves time and energy.

In 3D printing, photoinitiators help build objects one layer at a time. Many 3D printers use light between 385 and 405 nm. Photoinitiators need to match this light to work well. Some printers use near-infrared photoinitiators for safer use. These cost more money. The right photoinitiator gives high detail and less waste. It helps make complex shapes with smooth surfaces.

Photoinitiators make uv curing and 3D printing faster and more exact. They let people make things with fine details and strong shapes. Picking the right photoinitiator is important for each job. The kind of light and material both matter for how well it works.

| 애플리케이션 | Photoinitiator Role | 혜택 |

|---|---|---|

| UV Curing | Starts curing with UV light | Fast hardening |

| 3D 프린팅 | Enables layer-by-layer build | High resolution |

Photoinitiators in Ultraviolet Curing

UV Curing Process

Photoinitiators help turn liquids into solids in ultraviolet curing. When ultraviolet light shines on a surface, photoinitiators soak up the energy and start a chemical reaction. This reaction is called polymerization. The process happens fast because photoinitiators make reactive species that link small molecules together. Most factories use this method to make strong coatings, adhesives, and inks.

- UV curing light starts a reaction that changes liquid into solid in seconds.

- The reaction starts when ultraviolet light hits photoinitiators, which make reactive species to begin polymer crosslinking.

- Curing time with photoinitiators can be as short as milliseconds or a few seconds.

- Things like how strong the light is, how thick the material is, and the kind of photoinitiator can change the curing time.

- UV LED curing gives off all kinds of ultraviolet light, so photoinitiators work right away. This is faster than old ways that use heat or let things dry.

The curing process saves both time and energy. Factories use ultraviolet curing because it makes strong products quickly. Fast hardening is important for many businesses.

Ultraviolet Light Absorption

Photoinitiators soak up ultraviolet light at certain wavelengths. When the wavelength gets shorter, organic molecules take in more ultraviolet energy. Short ultraviolet wavelengths, between 200 and 280 nm, are soaked up near the surface. This means the curing does not go very deep. Most ultraviolet curing uses lights that cover many wavelengths. This helps the curing reach deeper layers.

- Photoinitiators in ultraviolet curing need strong light to get excited.

- Cationic photoinitiators usually need short ultraviolet light to work well.

- Most cationic photoinitiators used in factories soak up light below 350 nm. These need strong light to start working.

- Using short wavelengths can make ozone and heat. These things matter when checking how well ultraviolet curing works.

Factories must pick the right photoinitiator and light for the material and how deep they want to cure. How much light photoinitiators soak up changes how well curing works.

Reactive Species Generation

When photoinitiators soak up ultraviolet light, they get excited and make reactive species. These species start the curing by reacting with polymers. The most common reactive species are free radicals and cations.

- Photoinitiators soak up ultraviolet light and get excited.

- They make reactive species, usually free radicals or cations.

- These reactive species start curing by reacting with polymers.

- Type I photoinitiators make free radicals, like benzophenone and acetophenone.

- Type II photoinitiators make excited states that form free radicals, like thioxanthone and camphorquinone.

How much photoinitiator is used also changes how fast curing happens.

- Using a lot of photoinitiators can block light, making some parts cure less.

- Using less photoinitiator can help light go deeper but might not cure everything.

- The best amount depends on the mix and how deep you want to cure.

- Studies show that lowering photoinitiator from 0.25 wt% to 0.02 wt% makes thicker cured gel with more ultraviolet light.

- Conversion rates go up with more photoinitiator up to 1.25 wt%, but the best rate is at 0.75 wt%.

- Using less than 0.75 wt% makes conversion and glass-transition temperature lower.

Tip: Factories should try different amounts of photoinitiator and types of ultraviolet light to get the best results for their products.

Photoinitiators in ultraviolet curing make the process fast and work well. They help make strong materials in just seconds. Picking the right photoinitiator, light, and amount gives the best results.

Photoinitiator Mechanism in 3D Printing

Photoinitiators in Photopolymerization

Photoinitiators are very important in 3D printing with photopolymers. When a 3D printer uses ultraviolet light on liquid resin, the photoinitiators inside take in the energy. This starts a set of chemical reactions that turn the liquid into a solid. These steps help make objects with lots of detail.

- 래디컬 세대: The photoinitiators get energy from ultraviolet light. They split apart and make reactive particles called radicals.

- 시작: These radicals begin the polymerization process. They react with small molecules in the resin.

- 전파: The reaction keeps going as more radicals join with more molecules. This builds a strong, solid network.

다음이 있습니다. different kinds of photoinitiators. Norrish Type I photoinitiators break into two radical pieces when they get ultraviolet light. This is called a cleavage reaction or α-scission. Norrish Type II photoinitiators need a helper called a co-initiator. Together, they make two radicals—one from the photoinitiator and one from the co-initiator.

Tip: Picking the right photoinitiator helps control how fast and well the resin hardens. This choice changes how good the printed object will be.

Ultraviolet light makes this process fast and accurate. The printer can make tiny details because the reaction starts and stops quickly with each flash. This way also uses less material than older methods.

Layer-by-Layer Curing

3D printers make objects one thin layer at a time. Each layer starts as a liquid. The printer shines ultraviolet light on it, and the photoinitiators inside take in the energy. This makes the layer harden in the shape needed.

- The printer decides where the ultraviolet light goes. This lets it make very thin layers, sometimes thinner than a hair.

- Each new layer sticks to the one below. The printer can use a laser to make small holes that connect the layers. These holes help the layers join and make the object stronger.

- Thinner layers mean the printer can make objects with smooth surfaces and sharp details. The printer does not need to use extra supports inside the object. This saves material and cuts down on waste.

The layer-by-layer method gives the printer careful control over the shape and size of each part. The printer can make complex designs that are hard to do with other ways. Using ultraviolet light and photoinitiators makes the process quick and efficient.

| 기능 | 혜택 |

|---|---|

| Thin layers | High resolution |

| Laser connection holes | Stronger structure |

| No internal supports | Less material waste |

| Fast ultraviolet curing | Quick production |

Using photoinitiators, ultraviolet light, and careful layer control lets 3D printers make detailed, strong, and efficient objects. This technology changes how people design and build new things.

광개시제 유형

자유 라디칼 광개시제

Free radical photoinitiators are very important for uv curing. They start curing when uv light shines on them. There are two main groups: type i and type ii photoinitiators. Type i photoinitiators break apart after taking in uv energy. This makes free radicals. Type ii photoinitiators need a co-initiator to make free radicals. Both types are used in many ways.

Free radical photoinitiators help factories make coatings and adhesives fast. They work best when there is not much oxygen around.

The table below gives some examples:

| 광개시제 유형 | 설명 | 예제 |

|---|---|---|

| 유형 I | Makes free radicals after taking in uv light | Hydroxyacetophenone (HAP), Phosphineoxide (TPO) |

| 유형 II | Needs a co-initiator to make free radicals | Benzophenone and benzophenone-type photoinitiators |

양이온성 광개시제

양이온성 광개시제 do not work the same as free radical types. They start curing by making cations when uv light hits them. These cations help join molecules together. Cationic photoinitiators keep working even when the uv light is off. They can cure in the dark. They also do not stop working if there is oxygen. This makes them good for some factory jobs.

| 기능 | 양이온성 광개시제 | 자유 라디칼 광개시제 |

|---|---|---|

| 경화 속도 | Usually slower | Usually faster |

| Oxygen Sensitivity | Not bothered by oxygen | Can be stopped by oxygen |

| Curing After Light Removal | Keeps curing in the dark | Stops curing right after light is gone |

| Moisture Sensitivity | Can be changed by moisture | Not much changed by moisture |

| 애플리케이션 | Used for things like epoxides and vinyl ethers | Used for many different things |

Cationic photoinitiators make strong bonds and less shrinking. They are good for thick coatings and adhesives in uv curing.

애플리케이션 적합성

Picking the right photoinitiator depends on the job. Some work better with thick or colored materials. TPO is a good pick for thick resins in 3D printing. It keeps things strong without needing extra chemicals.

| 포토 이니시에이터 | 애플리케이션 | Notes |

|---|---|---|

| TPO | Thick resins in 3D printing | Used a lot, keeps things strong without extra chemicals |

Many things matter when choosing a photoinitiator. These include the material, color, curing method, light source, and how fast it cures. The table below shows what to think about:

| 요인 | 설명 |

|---|---|

| Prepolymer type | Different materials need different photoinitiators. |

| System color | Colored things need photoinitiators that work with color. |

| Curing method | Some jobs use hybrid photoinitiators for better results. |

| Light source wavelength | The photoinitiator must match the light source. |

| Light intensity and time | The right amount of light and time helps curing work best. |

| Curing environment | Oxygen and temperature can change how photoinitiators work. |

| Curing speed | Fast jobs need photoinitiators that cure quickly. |

| Curing depth | Thick things need photoinitiators that cure deep. |

| Final performance | The photoinitiator should be safe and not hurt the final product. |

Tip: Choosing the right photoinitiator makes products better and faster to make.

Factors Affecting Photoinitiator Effectiveness

Light Intensity and Wavelength

How well photoinitiators work depends on the uv light’s strength and color. Stronger light gives photoinitiators more energy. This helps things cure faster and more completely. If the material is thick, the uv light gets weaker as it goes through. The top layers might cure better than the bottom ones. It is important to pick a photoinitiator that matches the uv light for the best results.

The table below shows the best wavelength range for a common photoinitiator in 3D printing:

| 포토 이니시에이터 | Wavelength Range (nm) | 특성 |

|---|---|---|

| TPO | 350 – 430 | Norrish Type I, high polymerization rate, color stability |

Chemical Environment

The chemical environment changes how photoinitiators work. Photoinitiators soak up light between 250 and 450 nm. They turn this light into chemical energy. This makes free radicals and reactive cations. Temperature and moisture can make curing go faster or slower. High heat and dry air can change the color more and make it less stable. Room temperature and wet air help keep the color the same.

| 조건 | ΔE (Color Change) | Stability Description |

|---|---|---|

| High Temperature & Dry | 5.52 | Least color stability (greatest color change) |

| Room Temperature & Wet | 2.57 | Most color stability (least color change) |

Note: Factories should watch temperature and moisture to get the best curing.

재료 호환성

Photoinitiators need to work well with the material they are in. Some photoinitiators need hydrogen donors. This means they cannot be used with all polymers. Some can make by-products that smell or are not safe. This is a problem for things that touch skin or food. Special polymeric photoinitiators can help lower these problems, but they may not fix everything.

Common problems include:

- Photoinitiators moving to the surface, which can hurt how things work.

- Toxicity and yellowing as time goes by.

- Smell, unwanted color, and trouble mixing in.

- Needing more than one photoinitiator, which makes things harder to make.

Tip: Picking the right photoinitiator for the material and job helps stop these problems and makes safe, good products.

Photoinitiators are very important for UV curing and 3D printing. They help make the process fast, exact, and use less energy. Picking the right one makes products stronger and last longer. New types, like nanoparticle-bound and polymeric photoinitiators, use less energy and cure things faster.

- Faster curing and less energy help factories make more products.

- Better absorption means things can cure all the way with less photoinitiator.

- New designs stop photoinitiators from moving, smelling, or turning yellow.

Some photoinitiators can move to the surface or make by-products. This can be a problem for food packaging and biomaterials because it may not be safe.

자주 묻는 질문

What does a photoinitiator do in UV curing?

A photoinitiator takes in ultraviolet light. It starts a chemical reaction. This reaction changes liquid into solid. Factories use this to make coatings and adhesives fast and strong.

Can photoinitiators affect the color of finished products?

Yes, photoinitiators can change the color of products. Hot temperatures or dry air can make the color change more. Factories pick special photoinitiators to keep colors from changing.

Tip: Pick photoinitiators made to keep colors steady for important jobs.

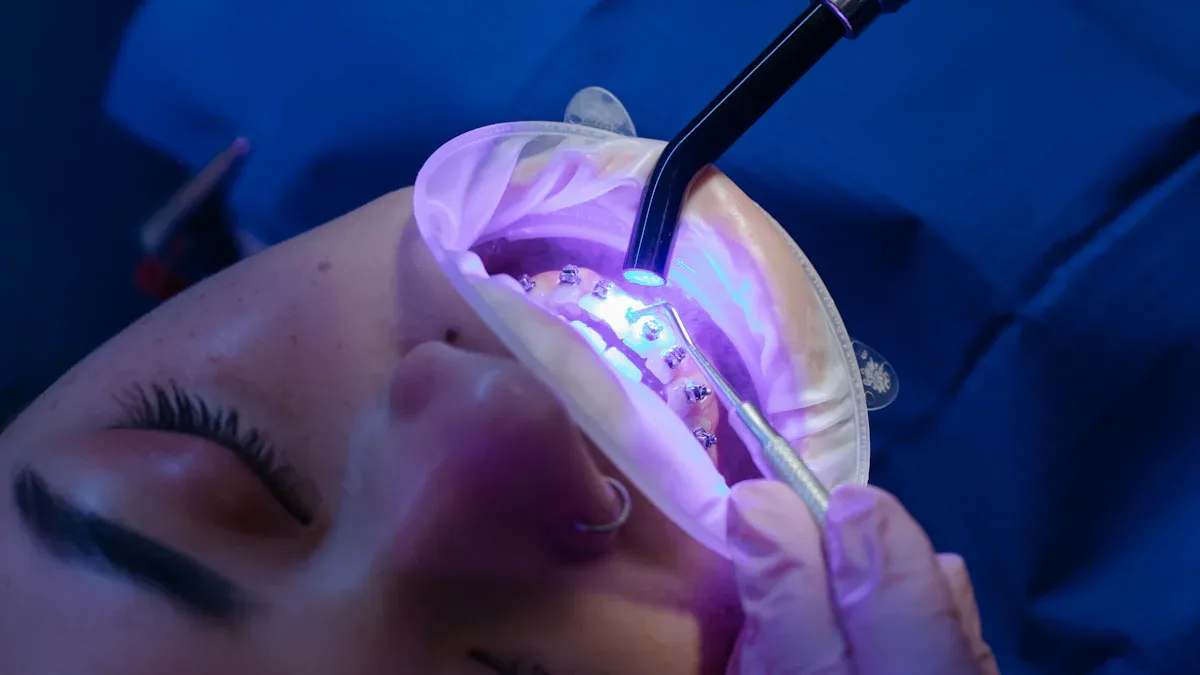

Are photoinitiators safe for medical or food products?

Some photoinitiators can move to the surface or make by-products. These might not be safe for skin or food. Companies use special kinds for medical and food packaging.

| 애플리케이션 | Safety Level |

|---|---|

| 의료 기기 | High (special types) |

| 식품 포장 | High (special types) |

Why do 3D printers use different photoinitiators?

3D printers need different photoinitiators for each light and resin. The right one gives better detail, faster curing, and less waste.

- TPO is good for thick resins.

- Some types work better for colored or deep prints.