Description

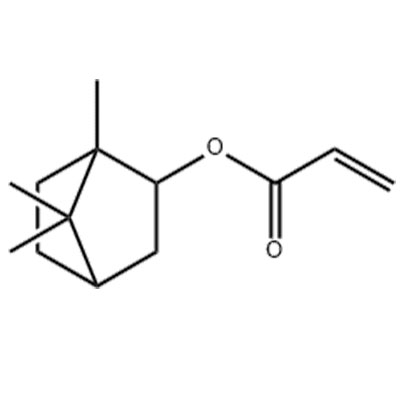

IBOA Monomer / Isobornyl acrylate CAS 5888-33-5

| Characteristic | IBOA |

| Appearance | Clear transparent |

| Formula Weight | 208 |

| Density g/ml | 0.984 |

| Refractive Index( 25℃ ) | 1.5040 |

| Viscosity()mPa.s | 7.5 |

| Closed Flash Point℃ | 93 |

| Glass Transition Temperature(Tg) ℃ | 90~100 |

| Surface Tension mN/m | 30 |

| Color (Pt-Co) | ≤30 |

| Ester content % | ≥98 |

| Moisture Content % | ≤0.2 |

| Polymer Content % | / |

| Inhibitor Content ppm | 100 |

IBOA Monomer USAGE

1. IBOA/IBXA has relatively high reactivity, weather resistance, low shrinkage, water resistance, chemical resistance; used in UV coatings (inks), adhesives, screen inks, photosensitive resins, photoresists.

2. Used in radiate curing coating (printing ink) as active diluents, it may effectively reduce the viscosity of the coating (printing ink), improve the performance of construction, and enhance leveling properties.

3. Usded as the active diluents of the epoxy-acrylic oligomer, it may reduce internal stress and volume shrinkage of the coating, thus improving the character index of radiation curing coating such as adhesion, volume shrinkage, anti-impact, mar resistance, weather resistance, and it won’t lose hardness and flexibility in its coating.

4. Used in protective coating of discs, it will attach extremely close with the surface of the texture on the disc. Moreover, has extremely enhances mar resistance and coating performance, and very distinctly improves the gloss of film.

5. Because IBOA has all sorts of merits (as listed above), it has been widely used in domains as active diluents of radiation curing coating, such as gloss varnish for metal, glass flexibility plastic film, engineering plastics as well as optical fiber coating, and has been simultaneously used in some special printing inks like outdoors spurt ink & news printing ink on thin-film of polyethylene.

1. Isobornyl acrylate is used in adhesives and special coatings, with high activity, high hardness and low shrinkage. Using Isobornyl acrylate as a reactive diluent for radiation curable coatings (inks) can effectively reduce the viscosity of the coatings (inks), improve construction performance, and improve the leveling of the coating.

2. Using Isobornyl acrylate as the reactive diluent of epoxy acrylic oligomer can significantly reduce the internal stress of the coating and reduce the volume shrinkage of the coating, thereby significantly improving the adhesion, shrinkage and impact resistance of the radiation cured coating Performance indicators such as resistance, scratch resistance and weather resistance, without reducing its hardness and flexibility.

3. If Isobornyl acrylate is used on the protective coating of optical discs, it has excellent adhesion and scratch resistance to the surface of fine lines, and has excellent coating properties and significantly improves the gloss of the coating film. Therefore, Isobornyl acrylate as a reactive diluent for radiation curing coatings has been widely used in metal finishing, glass flexible plastic film, engineering plastics and optical fiber coatings and other fields. At the same time, it is used in some special printing inks such as outdoor inkjet, polyethylene film and other materials. Used in the printing ink on the above.

4. Isobornyl acrylate is suitable for the manufacture of high Tg thermoplastic acrylic resin. Its products have high hardness, high alcohol resistance and heat resistance. And has good flexibility. Adhesion, moisture resistance, and weather resistance. It is a new type of acrylate polymer monomer with very characteristic structure. It is suitable for manufacturing soft plastic film coatings such as PET, PE, PP, and engineering plastic parts such as PE, PP, PC, etc. Decorative protective coating.

The table is the data table of the relative stress and volume shrinkage of the photocurable coating and the substrate when using different reactive diluents

| reactive diluent | functionality | Relative internal stress n | Volume shrinkage n% |

| TMPTA | 3 | 1.42 | 16.06 |

| HDDA | 2 | 1.11 | 13.33 |

| NPGDA | 2 | 13.86 | |

| CHA | 1 | 1.07 | |

| IBOA | 1 | 0.88 | 8.24 |

IBOA Packaging and Shipping:

Packing: 25kg/drum or 200 kg/drum

Delivery: with in 5-7 working days.

IBOA Storage:

Being kept in dry, clean warehouse with well ventilation.

Avoid exposing to light and heating.

Protecting the product from leakage, rain and insolation during transportation.

Contact Us Now!

If you need Price and Sample Testing, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@changhongchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

| CHLUMICRYL® AAEM Monomer | CAS 21282-97-3 | Acetylacetoxyethyl methacrylate |

| CHLUMICRYL® ADAMA Monomer | CAS 16887-36-8 | 1-Adamantyl Methacrylate |

| CHLUMICRYL® AMA Monomer | CAS 96-05-9 | Allyl methacrylate |

| CHLUMICRYL® BDDMA | CAS 2082-81-7 | 1,4-Butanedioldimethacrylate |

| CHLUMICRYL® BDDMP Monomer | CAS 92140-97-1 | 1,4-Butanediol Di(3-mercaptopropionate) |

| CHLUMICRYL® Bis-GMA Monomer | CAS 1565-94-2 | Bisphenol A Glycidyl Methacrylate |

| CHLUMICRYL® BZA Monomer | CAS 2495-35-4 | benzyl prop-2-enoate |

| CHLUMICRYL® BZMA Monomer | CAS 2495-37-6 | Benzyl methacrylate |

| CHLUMICRYL® CHA Monomer | CAS 3066-71-5 | cyclohexyl prop-2-enoate |

| CHLUMICRYL® CHMA | CAS 101-43-9 | Cyclohexyl methacrylate |

| CHLUMICRYL® DCPA Monomer | CAS 12542-30-2 | Dihydrodicyclopentadienyl Acrylate |

| CHLUMICRYL® DCPEMA Monomer | CAS 68586-19-6 | Dicyclopentenyloxyethyl Methacrylate |

| CHLUMICRYL® DCPMA Monomer | CAS 30798-39-1 | Dihydrodicyclopentadienyl methacrylate |

| CHLUMICRYL® DEAEA Monomer | CAS 2426-54-2 | 2-(diethylamino)ethyl prop-2-enoate |

| CHLUMICRYL® DEAM Monomer | CAS 105-16-8 | Diethylaminoethyl methacrylate |

| CHLUMICRYL® DMAEA Monomer | CAS 2439-35-2 | Dimethylaminoethyl acrylate |

| CHLUMICRYL® DMAEMA | CAS 2867-47-2 | N,M-Dimethylaminoethyl methacrylate |

| CHLUMICRYL® DMES | CAS 3570-55-6 | 2,2′-Thiodiethanethiol/Bis(2-mercaptoethyl) sulfide/Dimercapto diethyl sulfide/THIOCURE DMDS/Polythiol DMDS/Mercaptan DMDS |

| CHLUMICRYL® DMPT | CAS 131538-00-6 | THIOCURE DMPT |

| CHLUMICRYL® ECPMA Monomer | CAS 266308-58-1 | 1-Ethylcyclopentyl Methacrylate |

| CHLUMICRYL® EEMA | CAS 2370-63-0 | 2-ethoxyethyl 2-methylprop-2-enoate |

| CHLUMICRYL® EGDMA Monomer | CAS 97-90-5 | Ethylene glycol dimethacrylate |

| CHLUMICRYL® EGDMP Monomer | CAS 22504-50-3 | Ethylene glycol Bis(3-mercaptopropionate) |

| CHLUMICRYL® EHMA | CAS 688-84-6 | 2-Ethylhexyl methacrylate |

| CHLUMICRYL® EMA Monomer | CAS 97-63-2 | Ethyl methacrylate |

| CHLUMICRYL® EO10-BPADA Monomer | CAS 64401-02-1 | ethoxylated bisphenol A diacrylate |

| CHLUMICRYL® EO4-BPADA Monomer | CAS 64401-02-1 | ethoxylated bisphenol A diacrylate |

| CHLUMICRYL® HDCPA Monomer | CAS 79637-74-4 | Dicyclopentenyl acrylate (hydrogenation) |

| CHLUMICRYL® IBA Monomer | CAS 106-63-8 | Isobutyl acrylate |

| CHLUMICRYL® i-BMA | CAS 97-86-9 | Isobutyl methacrylate |

| CHLUMICRYL® MCPMA Monomer | CAS 178889-45-7 | 1-Methylcyclopentyl Methacrylate |

| CHLUMICRYL® MEMA | CAS 6976-93-8 | 2-Methoxyethyl Methacrylate |

| CHLUMICRYL® MPEG Monomer | CAS 26915-72-0 | MPEG Monomer |

| CHLUMICRYL® Muscomer Tricyclodecanedimethanol | CAS 26896-48-0 | Muscomer Tricyclodecanedimethanol |

| CHLUMICRYL® N,N-Dimethyl Acrylamide | CAS 2680-03-7 | N,N-Dimethyl Acrylamide |

| CHLUMICRYL® n-BMA | CAS 97-88-1 | n-Butyl methacrylate |

| CHLUMICRYL® PETMP Monomer | CAS 7575-23-7 | PETMP Monomer |

| CHLUMICRYL® Polythiol PM839 | CAS 72244-98-5 | Polythiol PM839 |

| CHLUMICRYL® TBAEMA | CAS 3775-90-4 | 2-(Tert-butylamino)ethyl methacrylate |

| CHLUMICRYL® THFMA Monomer | CAS 2455-24-5 | Tetrahydrofurfuryl methacrylate |

| CHLUMICRYL® ACMO Monomer | CAS 5117-12-4 | 4-acryloylmorpholine |

| CHLUMICRYL® DCPEOA Monomer | CAS 65983-31-5 | Dicyclopentenyloxyethyl Acrylate |

| CHLUMICRYL® DI-TMPTA Monomer | CAS 94108-97-1 | DI(TRIMETHYLOLPROPANE) TETRAACRYLATE |

| CHLUMICRYL® DPGDA Monomer | CAS 57472-68-1 | Dipropylene Glycol Dienoate |

| CHLUMICRYL® DPHA Monomer | CAS 29570-58-9 | Dipentaerythritol hexaacrylate |

| CHLUMICRYL® EO3-TMPTA Monomer | CAS 28961-43-5 | Ethoxylated trimethylolpropane triacrylate |

| CHLUMICRYL® EOEOEA Monomer | CAS 7328-17-8 | 2-(2-Ethoxyethoxy)ethyl acrylate |

| CHLUMICRYL® GPTA ( G3POTA ) Monomer | CAS 52408-84-1 | GLYCERYL PROPOXY TRIACRYLATE |

| CHLUMICRYL® HDDA Monomer | CAS 13048-33-4 | Hexamethylene Diacrylate |

| CHLUMICRYL® HEMA Monomer | CAS 868-77-9 | 2-hydroxyethyl methacrylate |

| CHLUMICRYL® HPMA Monomer | CAS 27813-02-1 | 2-Hydroxypropyl methacrylate |

| CHLUMICRYL® IBOA Monomer | CAS 5888-33-5 | Isobornyl acrylate |

| CHLUMICRYL® IBOMA | CAS 7534-94-3 | Isobornyl methacrylate |

| CHLUMICRYL® IDA Monomer | CAS 1330-61-6 | Isodecyl acrylate |

| CHLUMICRYL® IPAMA Monomer | CAS 297156-50-4 | 2-isopropyl-2-adamantyl methacrylate |

| CHLUMICRYL® LMA Monomer | CAS 142-90-5 | Lauryl methacrylate |

| CHLUMICRYL® NP-4EA Monomer | CAS 50974-47-5 | (4) ethoxylated nonylphenol |

| CHLUMICRYL® NPGDA Monomer | CAS 2223-82-7 | Neopentyl glycol diacrylate |

| CHLUMICRYL® PDDA | Phthalate diethylene glycol diacrylate | |

| CHLUMICRYL® PEGDA Monomer | CAS 26570-48-9 | Polyethylene Glycol Diacrylate |

| CHLUMICRYL® PEGDMA Monomer | CAS 25852-47-5 | Poly(ethylene glycol) dimethacrylate |

| CHLUMICRYL® PETA Monomer | CAS 3524-68-3 | PETA; 2-(Hydroxymethyl)-2-[[(1-oxoallyl)oxy]methyl]-1,3-propanediyl diacrylate; 3-(acryloyloxy)-2-[(acryloyloxy)methyl]-2-(hydroxymethyl)propyl acrylate |

| CHLUMICRYL® PHEA Monomer | CAS 48145-04-6 | 2-PHENOXYETHYL ACRYLATE |

| CHLUMICRYL® PO2-NPGDA | CAS 84170-74-1 | |

| CHLUMICRYL® TEGDMA Monomer | CAS 109-16-0 | Triethylene glycol dimethacrylate |

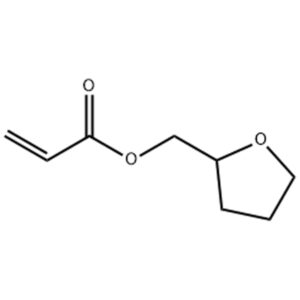

| CHLUMICRYL® THFA Monomer | CAS 2399-48-6 | Tetrahydrofurfuryl acrylate |

| CHLUMICRYL® TMPTA Monomer | CAS 15625-89-5 | Trimethylolpropane triacrylate |

| CHLUMICRYL® TMPTMA Monomer | CAS 3290-92-4 | Trimethylolpropane trimethacrylate |

| CHLUMICRYL® TPGDA Monomer | CAS 42978-66-5 | Tripropylene glycol diacrylate |

| CHLUMICRYL® UV Functional Monomers | Acrylic Monomers |

Corey Yonng –

The delivery is very fast and quality is good.We are very satisfied.