Tips Pembelian Monomer AAEM untuk Laboratorium dan Pabrik

When you buy aaem monomer for your lab or factory, look at how pure it is and check the CAS number. You need aaem for coatings, adhesives, and waterborne polyurethane–acrylate systems. Pick a supplier you can trust. Use a buyer’s guide to help you make good choices.

Hal-hal Penting yang Dapat Dipetik

- Always look at the purity and CAS number of AAEM monomer before you buy it. This makes sure you get the right and safe product for your work.

- Pilih trusted supplier who has the right certificates. This helps make sure your AAEM monomer is good and always the same.

- Use formulation software and advanced sensors to make your work better. These tools help you get good results and keep your product high quality.

AAEM Monomer Buying Tips

Key Factors for Labs and Factories

When you buy aaem monomer, think about a few things. Your lab or factory equipment must be ready for aaem. Reactors, mixers, and vessels need to be safe for use. Formulation software helps you find the best mix and settings. Spectrometers and chromatographs check aaem purity and keep results steady.

Special catalysts help reactions go faster. Advanced sensors let you watch reactions as they happen. Raw materials must stay pure all the time. If not, your polymer or polyurethane products might change. Security is important too. You should keep your formulas safe from hackers. You also need to think about cost and how well you make products.

Tip: Always make sure aaem is in stock before starting a project. A steady supply keeps your polymer and polyurethane work on schedule.

Here are some things to remember:

- Make sure your equipment can use aaem

- Use software to get the best results

- Check quality with spectrometers and chromatographs

- Use special catalysts for reactions

- Watch reactions with advanced sensors

- Keep raw materials pure

- Protect your formulas from cyber threats

- Balance cost and how well you make things

- Make sure aaem is always available

Quick Checklist for Buyers

Check how pure aaem monomer is before you buy. Purity changes how your lab or factory work turns out. If aaem is too high, pyrolysis can have problems. Taking out extra aaem can make bio-oil better. Watch for aaem building up on catalysts. This can stop them from working well. The table shows how purity affects your results:

| Evidence Description | Temuan |

|---|---|

| High levels of AAEMs negatively impact pyrolysis process | Purity levels of aaem monomer are crucial for optimizing laboratory and industrial outcomes. |

| Removal of AAEMs enhances yield and quality of bio-oil | Different elements affect reactions differently, so you must control inorganic element concentrations. |

| Accumulation of AAEMs on catalysts leads to deactivation | Alkali removal improves catalyst performance and pyrolysis efficiency. |

Always ask your supplier for the right papers. These papers show aaem is safe and good quality. The table below lists what you need:

| Documentation Type | Deskripsi |

|---|---|

| Purity Specifications | Minimum 98% for research applications; >99% for electronics-grade materials. |

| Sertifikat Analisis | Check silver content, residual solvent levels, and heavy metal impurities. |

| Compliance Documentation | Make sure the product follows REACH regulations and comes with SDS documentation. |

| Tolok Ukur Kinerja | Look for batch-to-batch consistency with analytical data like HPLC or ICP-OES. |

| Quality Management Systems | Ask for ISO certification and details about testing protocols. |

| After-Sales Support | You need technical assistance and reliable supply. |

Note: Always check if aaem is available before you order. Ask about how long it takes to get and if supply is steady, especially for polyurethane or polymer work.

Use this checklist before buying aaem monomer:

- Make sure your equipment and software work with aaem.

- Check purity and if each batch is the same.

- Get all the right papers.

- Ask if the supplier is reliable and has aaem in stock.

- Make sure you can get help for polyurethane and polymer uses.

AAEM Applications and Benefits

Use in Coatings and Adhesives

You can use aaem in lots of coatings and adhesives. This monomer gives you more ways to design a polymer. The special structure of aaem helps make products stick better and last longer. You get dual reactivity, so you can use different crosslinking methods. The acetoacetate group in aaem helps your polymer stick to surfaces and bond with metal ions. This makes your coatings harder and stops solvents from breaking them down.

Here is a table that shows the main advantages of aaem compared to other monomers:

| Keuntungan | Deskripsi |

|---|---|

| Dual Reactivity | You can use both methacrylate and acetoacetate groups for unique crosslinking and modifications. |

| Enhanced Adhesion | Your polymer will stick better to many surfaces because of the acetoacetate group. |

| Metal Chelation | The acetoacetate group bonds with metal ions, making coatings harder and more resistant. |

You also help the environment when you pick aaem. This monomer lets you make high-solids acrylic resins and self-crosslinkable emulsions. These products lower VOC emissions, so your coatings and adhesives are safer for people and the planet.

Tip: If you want coatings that dry at room temperature and lower VOCs, try aaem in your next polymer project.

Role in Waterborne Polyurethane–Acrylate

You can make waterborne polyurethane–acrylate systems work better by adding aaem. This monomer gives your polyurethane more strength and helps it fight off solvents. Studies show aaem helps your polymer stretch more and fix itself after damage. You get a tensile strength of 9.9 MPa and an elongation at break of 734%. The self-healing efficiency goes above 95%. These features make your coatings tough and last a long time.

When you use aaem, you add a special crosslinking site to your polyurethane. This makes your products stronger and lets them heal themselves. You can make coatings that are good for the environment and last longer.

Note: If you need strong, flexible, and self-healing coatings, aaem is a smart choice for your polyurethane and polymer systems.

Supplier Selection for AAEM

Checking Credentials and Certifications

You should check each supplier before buying aaem. A good supplier gives you clear papers and answers your questions. Pick a manufacturer that follows strict quality rules. Many top companies use ISO 9001 and ISO 14001 standards. These show the company cares about quality and the environment. Safety management systems help keep workers and products safe.

Here is a table that lists important certifications for aaem suppliers:

| Certification Type | Deskripsi |

|---|---|

| ISO 9001 | Quality management system standard ensuring consistent quality in products and services. |

| ISO 14001 | Environmental management system standard focusing on minimizing environmental impact. |

| Safety Management System | Framework ensuring safety protocols are followed in production processes. |

Always ask for these certificates. They help you trust the company. They also make sure your aaem works well in polyurethane and waterborne polyurethane–acrylate systems.

Importance of CAS Number 21282-97-3

You must check the CAS number when you buy aaem. The CAS number 21282-97-3 helps you know you have the right chemical. Many suppliers put this number on their labels and safety sheets. If you see this number, you know it is real aaem. This step keeps your polyurethane projects safe from mistakes.

Some companies, like Gantrade Corporation, sell aaem in big containers. You can buy aaem in 200 Kg drums for large factory needs. Always ask your supplier about packaging and delivery times. Good suppliers keep aaem in stock and ship fast. This helps you finish your polyurethane work on time.

Tip: Always check the CAS number and certifications before picking a supplier. This keeps your lab and factory safe and working well.

AAEM Monomer Quality and Specs

Purity and Chemical Properties

You must check aaem purity before using it. High purity gives better results in your projects. Most suppliers sell aaem with more than 98% purity. This amount helps chemical reactions work well. It also keeps your products safe.

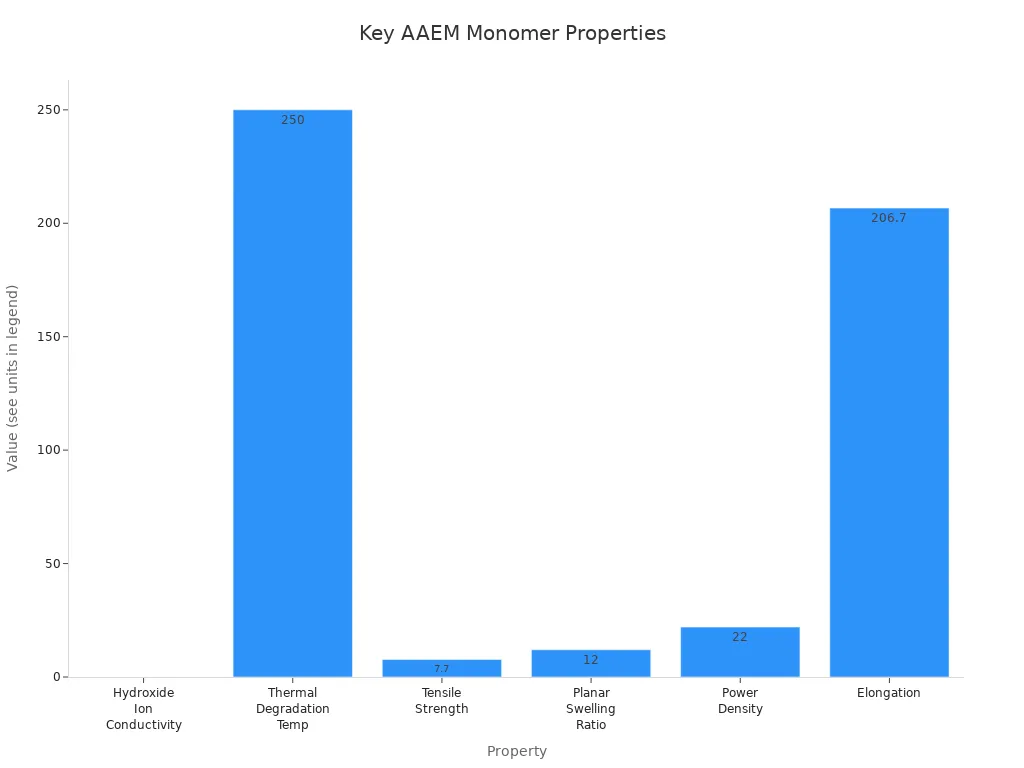

You should look at aaem’s chemical properties too. These properties change how your polymer acts. The table below lists important values for aaem:

| Properti | Nilai |

|---|---|

| Hydroxide Ion Conductivity | 0.00878 S cm−1 at 40 °C |

| Thermal Degradation Temperature | 250 °C |

| Kekuatan Tarik | 7.7 MPa |

| Planar Swelling Ratio | 12% at 40 °C |

| Power Density | 22 mW cm−2 at 55 mA cm−2 |

| Elongation | 206.7% in hydrate state |

Tip: High purity and strong chemical properties help you make tough coatings and bendy polymer films.

Batch Consistency and Documentation

You want every aaem batch to be the same quality. Batch consistency means you get good results each time. Suppliers use strict rules to keep aaem pure. They test each batch for water and dirt. Modern machines check the structure.

Here is a table that shows how suppliers keep aaem quality high:

| Quality Control Measure | Deskripsi |

|---|---|

| Rigorous Quality Control | Suppliers use strict rules to keep aaem pure. |

| Comprehensive Testing | Each batch gets tested for purity and moisture. |

| Analytical Equipment | Modern machines check the structure and find impurities. |

You should always ask for papers like certificates and test reports. These papers show aaem is good for your work.

Catatan: Good papers and batch consistency help your lab and factory avoid mistakes.

Pricing and Bulk Options

Comparing Quotes and Discounts

You want to pay the lowest price for aaem. Start by asking many suppliers for their prices. Look at each offer and see which is best. Some companies give you a better deal if you buy a lot at once. Buying in bulk saves money because the cost per unit goes down. Companies like NINGBO INNO PHARMCHEM CO.,LTD. often have good prices for big orders. This makes buying in bulk a smart move for your team.

Check for discounts that match what you need. You might find deals for buying more, sales during certain times, or rewards for loyal buyers. Always ask if you can get extra savings for ordering again. These deals help you spend less and keep your polymer and polyurethane work going well.

Tip: Ask if there are special prices for big aaem orders. You can often get a better deal if you plan ahead.

Contract Terms and Packaging

You should know the contract rules before you buy aaem. Read about delivery, payment, and how to return things. Good contracts keep your lab or factory safe from delays and extra fees. Suppliers with good prices usually have clear rules to help you plan your work.

Packaging is important for safety and easy use. You can get aaem in drums, totes, or small bottles. Big factories use 200 Kg drums for a steady supply. Labs may pick small bottles for easy use. Make sure the packaging keeps aaem clean and safe while shipping. Ask your supplier which package is best for your polymer and polyurethane needs.

| Packaging Type | Typical Use | Manfaat |

|---|---|---|

| 200 Kg Drum | Factory production | Bulk supply, cost savings |

| Small Bottle | Laboratory testing | Easy handling, less waste |

| Tote | Large projects | Flexible storage |

Note: Always check the packaging and contract rules before you order aaem. This helps you avoid problems and keeps your polymer and polyurethane work on time.

Application Compatibility

Matching AAEM Grade to Use

You need to pick the right aaem grade for your project. Each grade works best with certain chemicals and materials. For example, polyfunctional amines can crosslink aaem. This makes your material stronger. But it can also change how ions move and how stable things are. You should choose the best amine crosslinker for your needs. Some crosslinkers help keep your chemical and mechanical stability high. You also need to check if your polymer mixes well with aaem. Thermoplastics like poly(phenylene oxide) and polysulfone work well with aaem. They give you strong and stable results.

Here is a table to help you see what matters when you pick aaem for your project:

| Faktor | Deskripsi |

|---|---|

| Crosslinking Effects | Polyfunctional amines crosslink aaem, boosting strength but changing ion exchange and stability. |

| Selection of Chemistries | The right amine crosslinker keeps your chemical and mechanical stability high. |

| Polymer Compatibility | Thermoplastics like poly(phenylene oxide) and polysulfone work well with aaem. |

Technical Support for Waterborne Polyurethane–Acrylate

You get better results when you change how much aaem and ADH you use. This helps you control how your polymer acts and how stable your emulsion is. It also changes how your film works. Aaem makes your polyurethane tougher and helps it resist stains. You should add aaem late in the emulsion copolymerization process. This step helps your product work better and lowers yellowing. Aaem is safe to use because it does not have formaldehyde. It also has good toxicology data. The reactivity ratio of aaem lets you make random copolymers. This gives you the properties you want in your polyurethane. If you need help, ask your supplier for technical support. They can help you match aaem to your waterborne polyurethane–acrylate system.

- Change aaem and ADH levels for better polymer and film properties.

- Use aaem to make polyurethane tougher and more stain resistant.

- Add aaem late in the process to lower yellowing.

- Pick aaem for safer, formaldehyde-free products.

- Ask for technical support to get the best results in waterborne polyurethane–acrylate.

Tip: Always talk to your supplier if you have questions about using aaem in your polyurethane projects.

Shipping and Safety

Packaging and Delivery

You have to pick the right packaging for AAEM monomer. Good packaging keeps AAEM safe while it ships. Most suppliers sell AAEM in steel drums, plastic bottles, or totes. Factories usually buy 200 Kg steel drums for big orders. Labs like smaller bottles because they are easy to use.

Here is a table to help you see the packaging choices:

| Packaging Type | Terbaik untuk | Key Benefit |

|---|---|---|

| Steel Drum | Factory production | Strong and secure |

| Plastic Bottle | Lab use | Easy to handle |

| Tote | Bulk shipments | Flexible storage |

You should ask your supplier how long delivery will take. Good suppliers give you tracking numbers and clear shipping dates. Always check if the packaging is safe and meets the rules. This helps stop leaks or spills.

Tip: Keep AAEM in a cool, dry place and out of sunlight. This keeps AAEM safe and stable.

Safety Data and Compliance

You must read the Safety Data Sheet (SDS) before using AAEM. The SDS tells you about dangers, storage, and first aid. Always keep this paper in your lab or factory.

Look for these important safety papers:

- SDS (Safety Data Sheet)

- REACH registration

- Sertifikat Analisis

Suppliers with ISO certificates follow strict safety rules. You should wear gloves, goggles, and lab coats when using AAEM. Good airflow helps keep you safe from fumes.

Note: Never skip safety training. Learning the risks and safety steps keeps you and your team safe.

You need to make sure aaem monomer is pure. Check the CAS number to be sure it is right. Pick a supplier you can trust. Choose aaem monomer that works for your project. Here is a checklist to help you:

- Look at purity and CAS number

- Make sure the supplier is trusted

- See if aaem fits your project

- Read all safety papers

Always use safety steps before working with aaem monomer.

PERTANYAAN YANG SERING DIAJUKAN

What is the best way to ensure reliable sourcing of AAEM monomer?

Check if the supplier has the right certificates. Ask for papers that show each batch is good. Make sure the CAS number matches. Doing these things helps you get aaem on time and with good quality.

How does AAEM monomer help create a self-healable network?

AAEM monomer lets you make special polymer networks. These networks can fix themselves after they get damaged. This means your coatings can repair small breaks on their own.

Can I use AAEM with a dynamic disulfide-bearing crosslinking agent?

Yes, you can use AAEM with a dynamic disulfide crosslinking agent. This mix makes your polymer more bendy. It also helps your material bounce back after being stretched or pressed.