Endüstriyel UV Kürlemede Zorluklar ve Fırsatlar

In industrial fields such as UV coatings, inks, adhesives, and 3D printing, formulation engineers face a core dilemma every day: how to achieve superior final performance while maintaining production efficiency? Fotobaşlatıcılar, as the “engine” of photocurable systems, directly determine curing speed, curing depth, material properties, and the reliability of the final product.

Traditional selection methods often focus solely on comparing product parameters, neglecting the complex variables in real-world production scenarios. This guide will delve into the core pain points of 20 industrial scenarios, revealing how Changhong Chemical provides precise solutions for different industries through its “technology-driven scenario adaptation” strategy.

Part 1: Basic Principles and Common Selection Pitfalls

Q1: What are the core differences between free radical and cationic photoinitiators? How to choose between them in practical applications?

Scenario Pain Point: Engineers often struggle with choosing between these two systems when developing new formulations, especially when the product needs to balance multiple performance requirements.

In-depth Analysis:

Free radical systems (such as TPO, 819) have fast reaction speeds and lower costs, but are sensitive to oxygen and have a higher curing shrinkage rate (usually 5-10%). Cationic systems (such as iodonium salts, sulfonium salts) have lower curing shrinkage (1-3%), are not inhibited by oxygen, and have strong post-curing effects, but are sensitive to moisture and have a slower initial reaction speed.

Changhong Solution:

We don’t simply recommend a specific product, but instead establish a four-step selection matrix:

Substrate Compatibility Testing: Pre-test adhesion performance on different substrates such as plastics, metals, and glass.

Curing Environment Assessment: Analyze whether the production line is in a nitrogen environment, air environment, or a partially isolated environment.

Prioritization of Final Performance Requirements: Rank requirements such as weather resistance, flexibility, and chemical resistance by priority.

Mixed System Design: 70% of industrial applications actually use mixed systems. For example, our CHG-8010 series combines free radical and cationic photoinitiators at the molecular level, achieving both fast surface drying and complete deep curing, with shrinkage controlled to below 4%.

Q2: Why is the selection of photoinitiators for water-based UV systems so difficult? How can migration problems be fundamentally solved?

- Scenario Pain Points: Water-based UV coatings are growing rapidly in the wood and plastic coating fields, but traditional oil-soluble photoinitiators have poor dispersibility in the aqueous phase and high migration risks, especially in sensitive applications such as food packaging and toys.

- Real Industry Case: A children’s furniture company exporting to the EU repeatedly failed UV coating migration tests, facing substantial fines.

Changhong Technological Breakthrough:

We have developed a water-dispersible polymer anchoring technology:

- CHG-W Series Water-Based Photoinitiators: By introducing polyethylene glycol segments and carboxylic acid groups, the fotobaşlatıcımolecules possess self-emulsifying capabilities, forming stable dispersions of 50-100nm in the aqueous phase.

- Migration Blocking Mechanism: After polymerization, the active groups of the product cross-link with multifunctional monomers in the system, becoming “locked” in the polymer network. According to third-party testing, in an 8-week accelerated migration test, the migration amount of CHG-W803 was only 3% of that of traditional ITX.

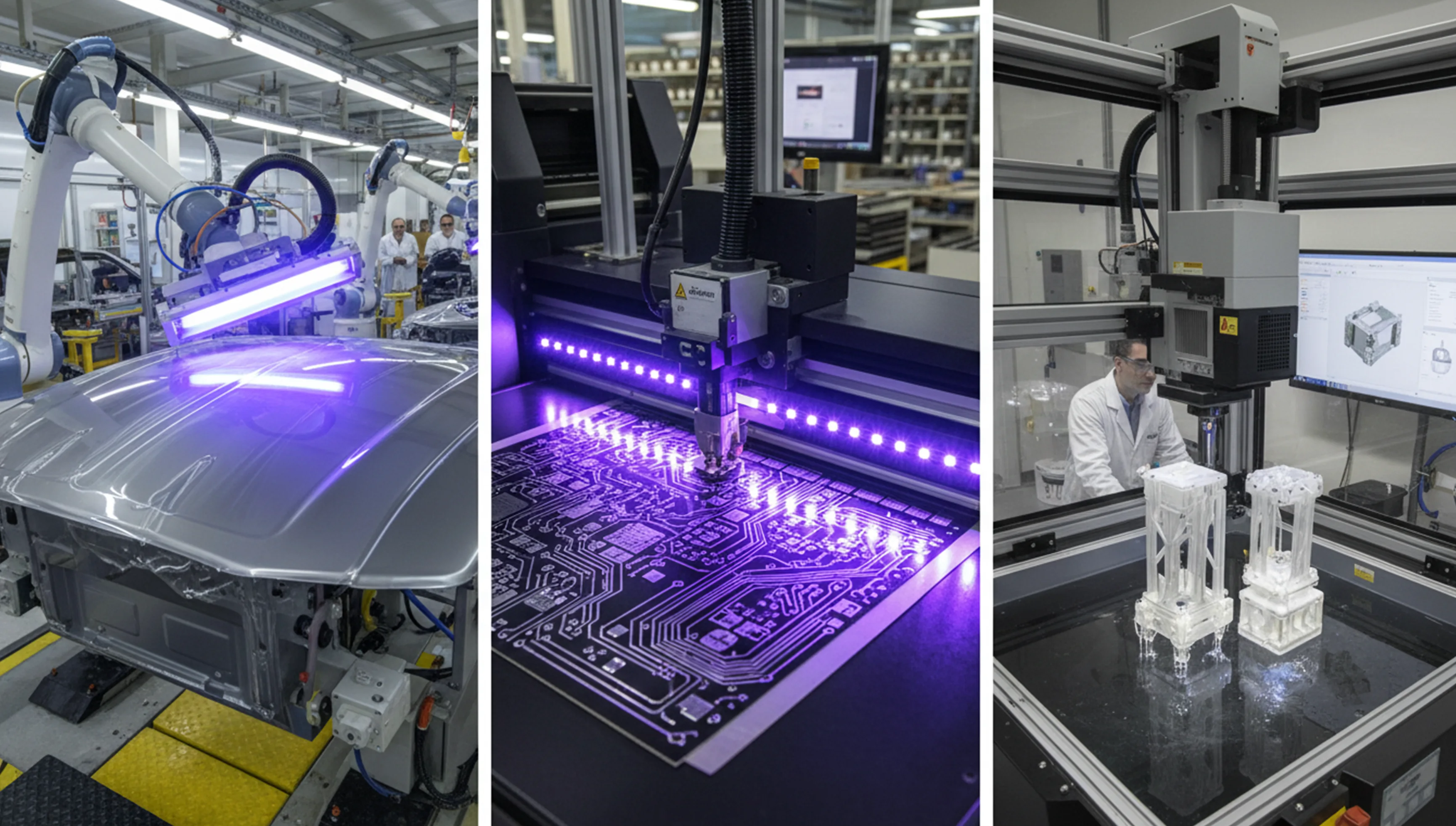

Part Two: In-Depth Solutions for High-End Manufacturing Scenarios

Q3: How to balance the conflict between “fast positioning” and “final strength” in UV curing of automotive structural adhesives?

Scenario Pain Point: Automotive body-in-white structural adhesives need to achieve initial positioning within 30 seconds (to meet production line cycle time), but the final strength takes 24 hours to fully develop, affecting subsequent processes.

We have developed a dual-stage triggered curing system:

Stage One: Fast Positioning (0-30 seconds)

- Using CHG-A501 high-activity acylphosphine oxide, gelation occurs in 3 seconds under a 1500mW/cm² LED light source.

- Initial shear strength reaches 2MPa, meeting the requirements for part handling.

Stage Two: Deep Strengthening (30 seconds – 24 hours)

- The system contains CHG-A502 latent cationic initiator, which reacts slowly at ambient temperature.

- Combined with our proprietary CH-Monomer A10 monomer, an interpenetrating network structure is formed.

- After 24 hours, the tensile strength reaches 35MPa, and the impact toughness is 50% higher than traditional solutions.

Process Adaptation Highlights:

We provide customers with a light intensity-time curve optimization solution for their production lines:

First station: High light intensity (2000mW/cm²) short-time irradiation (5 seconds) – achieving surface curing.

Second station: Medium light intensity (800mW/cm²) long-time irradiation (25 seconds) – ensuring deep curing.

Under natural conditions: The latent system continues to react, maximizing strength.

Part 3: Special Applications and Emerging Technological Challenges

Problem Description: UV-curable adhesives used in electronic packaging experience yellowing, cracking, and bubbling during reflow soldering, leading to chip packaging failure.

We address this challenge from three dimensions:

| Traditional approach: | Changhong Solution: | Performance improvements: |

| Ordinary free radical initiator | Cationic + epoxy resin system | Heat distortion temperature increased by +50℃ |

| Simple addition of inorganic filler | Surface-treated nano-SiO₂ gradient distribution | Coefficient of thermal expansion reduced by 60% |

| Single-point curing | Gradient illumination + post-curing process package | Internal stress reduced by 70% |

Q4: How to solve the problem of surface curing but incomplete curing at the bottom when UV curing thick coatings (>500μm)?

Scenario Pain Point: In thick coating applications such as industrial anti-corrosion coatings and floor coatings, traditional UV systems can only cure the top 200-300μm, leaving the underlying resin insufficiently reacted.

Our solution is based on the principle of light intensity attenuation compensation:

Technical Core: Gradient Absorption Fotobaşlatıcı Sistem

Surface Layer (0-200μm): CHG-D301 – High absorption rate, rapid reaction to form a “protective layer”

Middle Layer (200-400μm): CHG-D302 – Medium absorption rate, penetrates the surface layer to continue the reaction

Bottom Layer (400-500μm+): CHG-D303 – Low absorption rate, efficiently utilizes residual light

Combined with process innovation:

Dual-wavelength light source solution: We recommend customers use a 395nm + 365nm combined LED light source.

Viscosity adjustment technology: Adding our CHG-D310 flow additive reduces the system viscosity, allowing the photoinitiator to redistribute through diffusion during the curing process.

Result: In a 500μm transparent coating, the bottom curing degree increased from the traditional 65% to 92%, and the pencil hardness reached 2H.H

Q5: How can 3D printing photosensitive resins simultaneously meet the demands for high precision and low shrinkage?

Scenario Pain Point: Especially in dental models and precision parts printing, a shrinkage rate of 0.1% can lead to assembly failure.

We optimize the entire chain from materials to equipment and processes:

Material Level:

Low-shrinkage monomer design: Development of spirocyclic ester monomers, which undergo ring-opening polymerization during curing, with volume expansion compensating for shrinkage.

CHG-3D701 initiator: Optimized specifically for 405nm LED lasers, achieving a quantum efficiency of 0.85 (industry average 0.65).

Equipment Collaboration:

Established a parameter sharing library with mainstream 3D printer manufacturers, providing pre-optimized exposure parameter packages for different brands of equipment (such as Formlabs and UnionTech).

Practical Case: Dental Crown Printing

Traditional Resin: Shrinkage rate 1.8%, edge precision deviation ±50μm

CHG-3D701 System: Shrinkage rate 0.3%, edge precision ±15μm

Post-processing time reduced by 40% (no secondary thermal curing required)

Part 4: Process Adaptation and Production Stability

Q6: How should corresponding photoinitiators be selected for different light sources (mercury lamps, LEDs, lasers)?

Scenario Pain Point: When factories switch to LED lighting, they find that the curing efficiency of their original formulas decreases by 30-50%.

We have the most comprehensive light source testing platform, covering:

- Traditional mercury lamps: 200-450nm full spectrum

- LED light sources: 365nm, 385nm, 395nm, 405nm, 415nm mainstream wavelengths

- Special light sources:Excimer lamps (172nm, 222nm), laser light sources (355nm, 532nm)

Selection Guide:

- Mercury lamp to LED conversion: The key is the selection of long-wavelength photoinitiators. We provide a CHG-LED conversion evaluation package, including samples of three photoinitiators with different absorption wavelengths, allowing customers to quickly test the best matching solution.

- Multi-wavelength synergy:For complex shaped workpieces, a dual-wavelength photoinitiator system (CHG-DW401+DW402) is recommended to ensure sufficient curing even in shaded areas.

- Light intensity attenuation compensation: LED light sources experience approximately 10-15% light intensity attenuation after 2000 hours of use. Our CHG-LA series has a wider “dose-curing degree” platform, ensuring curing stability throughout the light source’s lifespan.

Q7: How to ensure sufficient curing in high-pigment content systems (such as colored paints and black UV inks)?

Scenario Pain Point: In black UV inks, carbon black absorbs most of the ultraviolet light, making curing extremely difficult. This usually requires adding excessive amounts of photoinitiators, leading to odor and migration problems.

We have developed a photon upconversion and scattering utilization technology:

Photon Redistribution Mechanism:

CHG-P401: Possesses fluorescent properties, absorbing short wavelengths (e.g., 365nm) and emitting long wavelengths (e.g., 405nm).

CHG-P402:scattering agent is coated on the surface of pigment particles, converting direct light into scattered light and increasing the light path.

Layered Curing Design:

Traditional Solution: Uniform addition of photoinitiator – excessive absorption in the surface layer, insufficient in the bottom layer.

Changhong Solution: Gradient distribution design

– Surface layer: Low concentration, preventing over-curing and brittleness

– Middle layer: Medium concentration, core reaction zone

– Bottom layer: High concentration, compensating for light intensity attenuation

Actual Results:

Black UV ink (5% carbon black content) is completely cured at a thickness of 50μm.

Total photoinitiator usage is reduced by 25%, and odor is reduced by 2 levels.

Improved storage stability (viscosity increase <5% after 6 months).

Conclusion: From Product Supplier to Technology Enabler

Through in-depth analysis of the 20 scenarios above, we can clearly see that the complexity of modern UV curing technology far surpasses simple product selection. Longchang Kimya, with its core strategy of “technology-driven scenario adaptation,” has built a full-link support capability from molecular design to process implementation.

Our core values:

– Deep understanding of scenarios: Not just providing product parameters, but understanding your production line, your end applications, and your real challenges.

– Full-cycle technical support: Providing continuous technical upgrades and process optimization from initial consultation to stable mass production.

– Quantifiable performance improvements: Every solution comes with clear performance improvement indicators and verification methods.

– Sustainable cost optimization: Helping customers establish long-term cost advantages through technological means, not just simple price reductions.

The future of UV curing technology lies in precise matching and deep collaboration. Let’s explore together and transform the precision of chemistry into industrial value.