A Comprehensive Guide to Using AMA Monomer in Polymer Synthesis

You can use AMA Monomer CAS 96-05-9 to enhance the performance of your polymers. When you add AMA Monomer CAS 96-05-9, your polymer will have improved adhesion, increased strength, and better heat resistance. Many industries rely on AMA Monomer CAS 96-05-9 to make their products more durable and efficient. If you want your materials to be tougher and longer-lasting, AMA Monomer CAS 96-05-9 is an excellent choice for polymer manufacturing. You’ll notice the difference that AMA Monomer CAS 96-05-9 makes in helping you create superior products.

Principais conclusões

- AMA Monomer helps polymers stick better and become stronger. It also makes them resist heat more. Using AMA in making polymers lets us create tough materials. These materials work well in many fields, like medicine and cars. When AMA is used alone, it makes strong and bendy polymers. These are great for coatings and glues that face tough situations. When AMA is mixed with other things, it can be changed for special uses. This gives better control over how the material acts and works. Safety is very important when using AMA. Always wear safety gear and keep it stored the right way to stop accidents.

AMA Monomer (Allyl Methacrylate, CAS 96-05-9) Overview

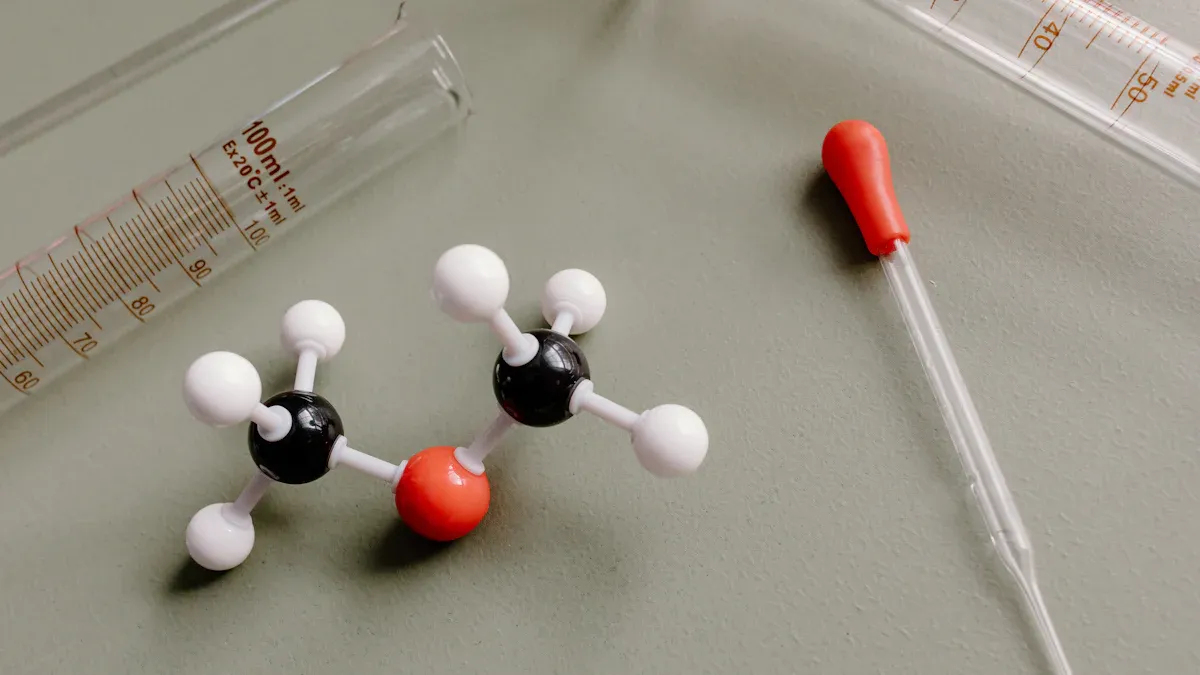

Chemical Structure and Key Properties

AMA is a reactive monomer with a special structure. It has an allyl group and a methacrylate group. These groups give AMA some helpful properties. AMA can make materials strong and flexible. The double bonds in AMA let it work in many polymerization processes. AMA is different because it can form crosslinks. Crosslinks make polymers tougher and better at handling heat.

Here are some important properties of AMA:

- High reactivity during polymerization

- Ability to form crosslinked networks

- Improves mechanical properties

- Enhances thermal stability

- Increases adhesion in finished products

AMA works in many polymerization methods. You can use it for biomedical devices, adhesives, and coatings. AMA helps you get the right properties for advanced uses.

Role in Polymer Synthesis

AMA helps your materials work better in polymer synthesis. It is a reactive monomer that helps with crosslinking. Crosslinking makes polymers stronger and gives them better properties. Adding AMA to pmma makes it tougher and more heat-resistant. AMA also lets you make special polymers for biomedical uses.

You might want to know how AMA is different from other methacrylates. The table below shows how they are not the same:

| Monomer Type | Extinction Coefficient | Reactivity in Polymer Synthesis |

|---|---|---|

| Methyl Methacrylate (MMA) | Mais alto | More reactive due to greater conjugation |

| Methyl Acrylate (MA) | Inferior | Less reactive compared to MMA |

AMA gives a good mix of reactivity and crosslinking in pmma. You can use AMA in pmma polymerization for better strength and heat resistance. AMA helps you make polymers that meet tough rules for biomedical and industrial uses. You can trust AMA to make your pmma products stick better, last longer, and handle heat.

AMA Monomer Applications in Polymer Synthesis

AMA can help you make better polymers. You can use AMA to change how pmma and other polymers act. AMA helps your materials last longer and work well in hard places. It makes your polymers stick better, get stronger, and handle heat.

Homopolymerization Uses

AMA works in homopolymerization to make strong and bendy polymers. If you use only AMA, you get a polymer with special features. AMA has double bonds that help make crosslinked networks. These networks make pmma tough and good with heat. Homopolymerized AMA is used in coatings and adhesives. These need to stick well and not break easily. AMA-based pmma keeps its shape and strength even with heat.

- AMA homopolymerization gives you:

- Good thermal stability

- Strong mechanical properties

- Better sticking for coatings and adhesives

Tip: Use AMA homopolymerization if you want coatings that last and do not get damaged.

Copolymerization for Functional Polymers

You can mix AMA with other monomers to make special polymers. Copolymerization lets you pick the properties you want for pmma. You can use different polymerization methods for the best results. Here is a table with some common copolymerization ways using AMA:

| Técnica | Descrição |

|---|---|

| ATRP | This method controls how long the polymer chains are and their structure. |

| RAFT | This technique helps make polymers with special shapes and uses. |

| Self-condensing vinyl polymerization | This way uses AB* monomer-initiators and vinyl monomers to make branched polymers with better control. |

These methods help you make pmma with cool features. You can add AMA to pmma to make it bend more or handle heat better. You can also make polymers for medical uses. These need to be safe and strong. AMA helps you do this.

- Copolymerization with AMA gives you:

- Custom features for different uses

- More control over polymer shape

- Better coatings and adhesives

Specialty Polymers and Advanced Materials

AMA helps you make special polymers for tough jobs. You can use AMA to make pmma that works in hard places. These special polymers handle heat and are very strong. You can use them in electronics, car parts, and medical devices. AMA lets you make polymers that meet strict rules.

- Specialty polymers with AMA offer:

- Better durability

- Resistance to chemicals and heat

- Great sticking for coatings and adhesives

AMA helps you make advanced materials that last and work well.

Industrial Uses: Adhesives, Sealants, Coatings

Many industries use AMA in their products. You find AMA in adhesives, sealants, and coatings. These need to stick well and stay strong. AMA makes pmma better in these uses. AMA helps coatings protect surfaces from heat and chemicals. AMA is also used in adhesives that hold things together in tough places.

- Industrial uses for AMA include:

- Coatings that protect metal and plastic

- Strong adhesives for building and cars

- Sealants that fight heat and chemicals

Note: AMA helps you make coatings and adhesives that last and work well in real life.

AMA is a useful reactive monomer. It helps you make better pmma and other polymers. You can use AMA in many ways to get the features you want. AMA makes your coatings and adhesives stronger and more reliable.

Benefits and Limitations of AMA in Polymerization

Advantages for Polymer Performance

Você pode usar ama in many steps to make your materials better. This monomer helps you get stronger pmma with improved features. Adding ama helps pmma stand up to heat and stay tough. It also makes coatings last longer and stick well. Many products need these features, especially adhesives and coatings.

- Ama adds more crosslinking during polymerization. This makes pmma stronger and less likely to break.

- You get better thermal stability. Your pmma will not melt or lose shape easily.

- Ama helps coatings protect surfaces from damage. These coatings work well in harsh places.

- In adhesives, ama improves sticking power. Your products hold together better.

- You can use ama in biomedical applications. It helps you make safe and strong materials for medical devices.

Tip: If you want your polymer to last longer and work in tough places, choose ama for your synthesis.

Challenges and Drawbacks

You should know the limits of ama in polymerization. Using too much ama can make pmma too hard or easy to break. You may need to change your process to get the right features. Ama can slow down polymerization if you do not use the right settings.

| Challenge | Impact on Applications |

|---|---|

| High crosslinking | Can make pmma brittle |

| Slow polymerization | Longer synthesis time |

| Handling and storage | Needs care due to reactivity |

- Some coatings may get too stiff if you use too much ama.

- In adhesives, too much ama can lower flexibility.

- You must watch your process to avoid problems.

Note: Always test your synthesis with ama to find the best mix of features for your products.

Practical AMA Polymer Synthesis Guidelines

Selecting AMA Monomer for Polymerization

You need to pick the right ama for your project. High-purity allyl methacrylate works best in pmma polymerization. Always check the purity before starting. Impurities can change how your polymer acts. This can affect how you use it. Use more ama if you want extra crosslinking in pmma. Use less ama if you want pmma to bend more. Think about what you need before you choose.

Tip: Using high-purity allyl methacrylate helps your pmma stay the same every time. This makes your projects work better.

| AMA Selection Step | O que você deve fazer |

|---|---|

| Check purity | Use high-purity allyl methacrylate |

| Match to application | Adjust ama amount for properties |

| Test before scaling | Run small-scale synthesis first |

Free Radical Polymerization Methods

You can use free radical polymerization to make pmma with ama. This method is good for many uses. Atmospheric-pressure plasma-induced free-radical polymerization works well for allyl monomers like ama. You get fast results and keep the chemical structure. You can do this at room temperature without using solvents. This makes it safe and easy to use for pmma. Watch out for monomer fragmentation. It can lower how many functional groups stay in your polymer. Allyl monomers sometimes keep fewer groups than vinyl monomers.

There are other free radical polymerization methods for pmma. These include bulk, solution, and emulsion polymerization. Each way gives you different results. Pick the one that fits your needs.

| Método | Features and Benefits |

|---|---|

| Atmospheric-pressure plasma | Fast, solvent-less, mild conditions |

| Bulk polymerization | Simple, good for large-scale pmma |

| Solution polymerization | Easy to control, good for specialty pmma |

| Emulsion polymerization | Makes small particles, good for coatings |

Note: Try different polymerization methods to see which one works best for your project.

Handling and Safety Considerations

You must follow safety rules when working with ama. This monomer can catch fire easily. Store it in insulated containers or keep it cold. Add an inhibitor like hydroquinone to stop unwanted polymerization. If there is a fire, containers can explode because of polymerization. Be ready with firefighting tools. Wear protective clothes to keep your skin safe.

- Ama vapors can bother your eyes and lungs.

- Liquid ama can make your skin itch or hurt.

- Breathing or touching ama may make you feel sick.

Set up safe distances in your workspace. Follow rules for fighting fires and for other emergencies. Keep first aid supplies close by.

Safety tip: Always wear gloves, goggles, and a lab coat when you use ama. Store high-purity allyl methacrylate away from heat and sunlight.

Troubleshooting Polymer Synthesis Issues

You might have problems when making pmma with ama. If your polymer breaks easily, you may have used too much ama. If the process is slow, check your temperature and initiator. Monomer fragmentation can lower how many functional groups stay in your polymer. Change your process to fix these problems.

- If pmma does not act right, try different ama amounts.

- If you see unwanted polymerization, check your inhibitor and storage.

- If you need flexible pmma, use less ama.

| Problema | What You Can Do |

|---|---|

| Brittle polymer | Lower ama amount |

| Slow polymerization | Increase temperature or initiator |

| Unwanted polymerization | Add more inhibitor, improve storage |

| Poor retention of properties | Change polymerization method |

Tip: Always run small tests before making a lot of polymer. This helps you find the best way for your project.

You can make strong and reliable pmma if you follow these steps. Always be safe and test your process to get the results you want.

Case Studies: AMA in Polymer Applications

Real-World Examples in Polymer Synthesis

AMA helps in lots of polymer projects. One example is making pmma-go nanocomposites. AMA makes pmma stronger and better with heat. These nanocomposites protect metal from rust. You can use them for anticorrosive coatings. AMA is also used in medical fields. It helps make pmma for medical devices. These devices need to be safe and strong. You can use pmma-go composites for bone repair. They help bones heal faster.

| Área de aplicação | How AMA Helps |

|---|---|

| Anticorrosive coatings | Makes pmma-go nanocomposites stronger |

| Biomedical applications | Improves pmma for implants |

| Eletrônicos | Helps pmma handle heat |

Tip: AMA lets you make nanocomposites for many uses.

Insights from Industry and Research

Many studies talk about AMA in polymerization. Researchers use AMA to make pmma-go nanocomposites with better features. These nanocomposites work well in medicine. You can use them for drug delivery. They are also used in sensors. Sensors need strong and bendy materials. AMA helps you get these results. Experts say AMA makes pmma last longer. You can trust AMA for advanced uses.

- AMA is used to make better pmma-go nanocomposites.

- You find pmma-go nanocomposites in medical uses.

- You use pmma-go nanocomposites for coatings that stop rust.

- You see pmma-go nanocomposites in electronics and sensors.

Note: AMA helps you find new ways to use nanocomposites. You can make better materials for the future.

You have learned how AMA monomer can improve your polymer projects. It gives you stronger materials and better results in synthesis. You should try AMA if you want to make your products last longer or work in tough places. Think about testing AMA in your next project. You can also talk to experts or read more studies to learn new ways to use it.

PERGUNTAS FREQUENTES

What is AMA monomer used for in polymer synthesis?

AMA monomer makes polymers stronger and helps them handle heat. It helps materials stick better and last longer. Many companies use AMA in adhesives, coatings, and sealants.

Can you use AMA monomer in biomedical engineering?

Yes, AMA monomer is used in biomedical engineering. It helps make safe and strong materials for medical devices. These materials work well inside the body and last a long time.

How does AMA improve graphene oxide nanocomposites?

AMA monomer makes graphene oxide nanocomposites tougher and more bendy. It gives better protection from rust and heat. These nanocomposites are good for electronics and coatings.

What safety steps should you follow when handling AMA monomer?

Wear gloves, goggles, and a lab coat for safety. Store AMA in a cool place away from sunlight. Add an inhibitor to stop unwanted reactions. Keep first aid supplies close by.

Can AMA monomer be used in nanohybrid polymer composites?

AMA monomer can be used in nanohybrid polymer composites. It helps give better strength and heat resistance. These composites are used in cars and electronics.