Description

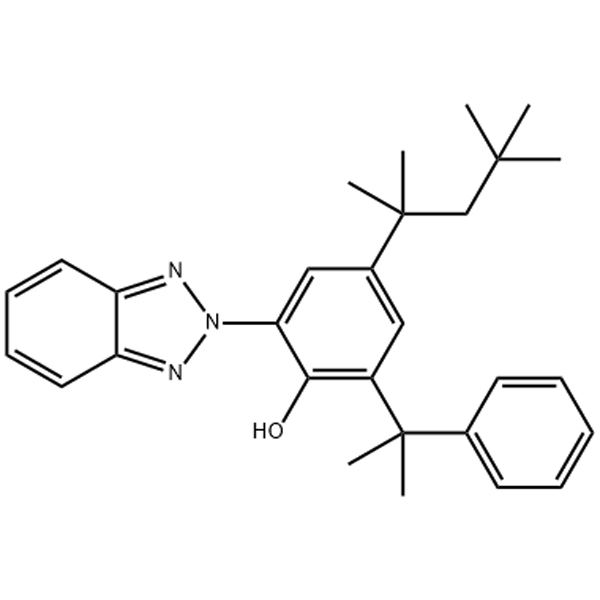

UV-928 CAS 73936-91-1

| Appearance | light yellow crystal |

| Content | ≥98% |

| Melting point | 108-112°C |

| Volatile matter | ≤ 0.3% |

| Ash | ≤ 0.1% |

| Light transmittance: | 460nm: ≥ 97% |

| 500nm: ≥98% |

UV-928 Usage

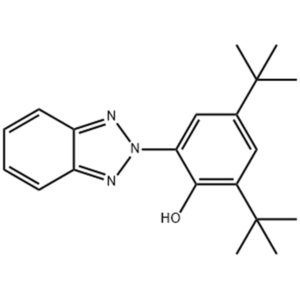

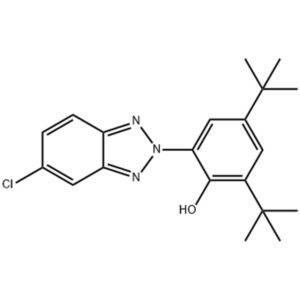

1. UV absorber UV-928 is a benzotriazole UV absorber, capable of absorbing 270-380nm UV light, with peak absorption of 303nm and 343nm. It has good compatibility, low volatility, good dispersibility, low migration, good thermal stability and high absorption efficiency. It is suitable for high temperature curing systems, powder coatings, coil steel coatings, and especially for surface coating of coatings. Combined with light stabilizers UV292 and UV123, it can significantly improve the durability of the coating and inhibit the loss of light, discolouration, cracking and delamination of the coating. The general dosage is 1.0-3.0%.

2. Applicable to: UV absorber for high performance coatings. With a wide range of absorption properties, it can effectively protect coatings and other photosensitive materials. Also has high solubility, high temperature resistance and good environmental durability, especially suitable for high temperature curing systems, such as powder coatings, coil steel coatings, etc.

Contact Us Now!

If you need COA, MSDS or TDS of UV Absorber, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@changhongchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.