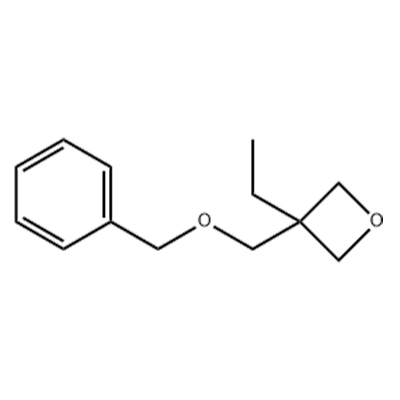

1. UV Curing Coating Systems:

As a reactive diluent for cationic UV-curing coatings, it reduces formula viscosity, improves the wettability and coatability of the coating on the substrate, and provides the cured coating with good flexibility, adhesion, and chemical resistance. It is suitable for surface protection and decoration of substrates such as metals, plastics, and paper.

2. Cationic Thermosetting Systems:

Used in cationic thermosetting resin formulations, it reduces system viscosity, improves processing ease, and enhances the toughness of the cured product. It is commonly used in the preparation of high-performance industrial protective coatings and adhesives.

3. Electronic Materials:

It can be used in encapsulation materials for electronic components and solder mask inks for printed circuit boards. Its low viscosity improves the processing performance of the materials, and the cured coating provides excellent insulation and moisture and heat resistance, ensuring the stability of electronic components.

4. Optical Materials Preparation:

Applied in optical films and optical adhesives, it reduces volume shrinkage during the curing process, improving the dimensional stability and optical performance of optical components, meeting the high-precision requirements of the optical field.

5. Ink Industry:

As a reactive diluent for UV-curing inks, it reduces ink viscosity to suit different printing processes, such as screen printing and flexographic printing. The cured ink film has good abrasion resistance and weather resistance, suitable for packaging printing and other applications.

6. Adhesives and Sealants:

Used in the preparation of cationic curing adhesives and sealants, it improves the fluidity of the product and enhances the bonding strength and sealing effect on various substrates, suitable for bonding and sealing industrial components.