5 Big Benefits of Using Photoinitiator 819 DW in Coatings

You can get five big benefits when you pick Photoinitiator 819 DW for coatings:

- It cures fast and helps your work go quicker.

- It keeps colors bright and new for a long time.

- It cures thick or colored coatings all the way through.

- It works well with water-based and green systems.

- It does not move much, so coatings are safer and follow rules.

You can find Photoinitiator 819 DW used on wood, plastic, and textiles. It is also in water-based coatings. Many businesses use it for printing, packaging, and home décor laminates. When you use it, you get fast UV curing, use less energy, and get strong, shiny finishes that do not scratch or get damaged by chemicals.

Belangrijkste opmerkingen

- Fotoinitiator 819 DW helps coatings dry fast. You can finish work sooner and use less energy.

- It keeps colors bright and stops yellowing. Your products will look new and nice for a long time.

- This photoinitiator dries thick and colored coatings well. The finish is strong and smooth with no soft spots.

- It works with water-based and eco-friendly systems. You can use it for many things, and it is better for the environment.

- Low migration risk means it is safe for things like food packaging and toys. It helps you follow safety rules.

1. Fast Curing with Photoinitiator 819 DW

Rapid UV Cure

You want your coatings to dry fast and look great. Fotoinitiator 819 DW helps you do both. When you use this photoinitiator, you can cure coatings in seconds under UV light. This means you finish jobs faster and save energy. You do not have to wait long for surfaces to dry. You can move on to the next step quickly.

Many industries use Photoinitiator 819 DW for wood, plastic, and graphic arts. You see it in printing, packaging, and even furniture. It works well in both clear and pigmented systems. You get a strong, even finish every time.

Tip: Fast curing helps you reduce dust and dirt sticking to wet coatings. Your finished product looks cleaner and more professional.

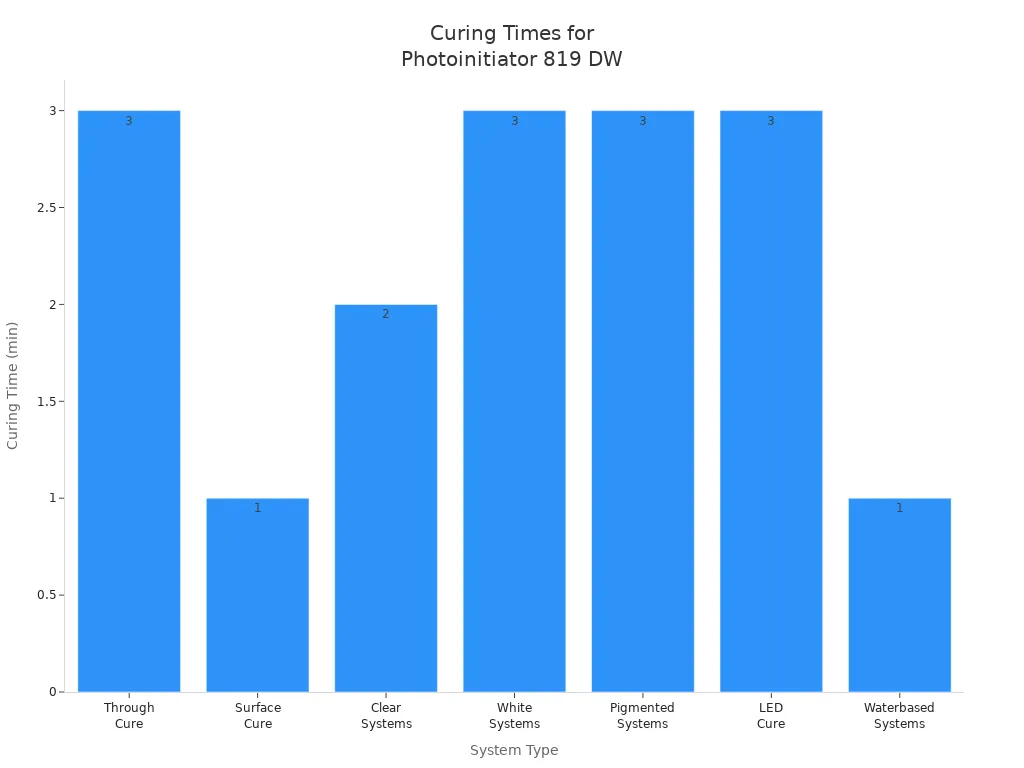

Here is a table that shows typical curing times for different systems with Photoinitiator 819 DW:

| System Type | Curing Time (seconds) |

|---|---|

| Through Cure | 3 |

| Surface Cure | 1 |

| Clear Systems | 2 |

| White Systems | 3 |

| Pigmented Systems | 3 |

| LED Cure | 3 |

| Waterbased Systems | 1 |

You can also see how fast these systems cure in the chart below:

Complete Cure in Thick Layers

You may need to coat thick or colored surfaces. Some photoinitiators cannot cure these layers all the way through. Photoinitiator 819 DW solves this problem. It lets UV light reach deep into the coating. You get a full cure, even in thick or filled coatings.

This means you do not see sticky spots or soft areas. Your coating feels hard and smooth from top to bottom. You can trust the finish to last longer and resist damage. Whether you work with wood, plastic, or textiles, you get reliable results every time.

2. Superior Color Stability

Reduced Yellowing

You want your coatings to stay bright and fresh. Many coatings can turn yellow from sunlight or heat. Yellowing makes surfaces look old or dirty. You can stop this by picking the right photoinitiator.

Fotoinitiator 819 DW keeps coatings clear and true to color. It works in clear and pigmented systems. You do not need to worry about white or light coatings turning yellow. This photoinitiator blocks the reactions that cause yellowing. Your surfaces stay bright and nice.

Opmerking: Less yellowing matters for furniture, packaging, and printed things. Customers want to see bright colors, not faded or yellow finishes.

Here are some things that cause yellowing in coatings:

- UV light

- High heat

- Chemical reactions with other ingredients

You can trust Fotoinitiator 819 DW to fight these problems. It helps your coatings look new.

Maintains Color Over Time

You want coatings that last a long time. Color stability means surfaces keep their look for months or years. Fotoinitiator 819 DW gives you this benefit. It protects coatings from fading or changing color.

Many industries see these benefits:

- Wood finishes stay rich and natural.

- Plastic parts keep their bright colors.

- Textiles hold their patterns and colors.

Check the table below to see how Fotoinitiator 819 DW compares to standard photoinitiators in color tests:

| Test Condition | Standard Photoinitiator | Fotoinitiator 819 DW |

|---|---|---|

| After 500h UV Light | Noticeable Yellowing | No Yellowing |

| After 1 Year Aging | Faded Colors | Colors Stay Bright |

You can feel good knowing your products will look great for a long time. Customers notice when colors stay sharp and surfaces look clean.

3. Deep Cure for Pigmented and Thick Coatings

Effective in Opaque Systems

Sometimes you need coatings that cover well and look solid. Pigmented and thick coatings can block light. This makes it hard for some photoinitiators to work. Fotoinitiator 819 DW fixes this problem. It absorbs light at longer wavelengths. This lets it reach deep into the coating. You get a full cure, even if the coating is dark or has lots of color.

If you use this photoinitiator, you do not get sticky spots. There are no soft layers under the surface. The whole coating gets hard and smooth. This helps your products last longer and look nice. You can use it for plastics, textiles, and other materials. These need strong and deep curing.

Tip: Deep curing helps your coatings resist scratches and damage. You get a finish that stands up to daily use.

Reliable for Multiple Substrates

You want your coatings to work on many surfaces. Photoinitiator 819 DW gives you this choice. It works well on metal, paper, leather, and more. You can use it for packaging, car parts, or decorations.

Here is a table that shows how it works on different surfaces:

| Substraat | Curing Quality | Surface Hardness | Kleurstabiliteit |

|---|---|---|---|

| Metaal | Uitstekend | Hoog | Zeer goed |

| Paper | Uitstekend | Medium | Uitstekend |

| Leather | Zeer goed | Hoog | Zeer goed |

| Plastic | Uitstekend | Hoog | Uitstekend |

| Textile | Zeer goed | Medium | Zeer goed |

Photoinitiator 819 DW makes pigmented and thick coatings stronger. Your coatings do not turn yellow from UV light. They stay tough over time. This makes your products last longer and stay stable, even in hard conditions.

You can trust this photoinitiator for deep, even cures on many surfaces. Your coatings will look good and last longer, wherever you use them.

4. Broad Compatibility in Formulations

Works in Water-Based Coatings

You want a photoinitiator that works with many coatings. Fotoinitiator 819 DW gives you this choice. Older photoinitiators do not mix well with water-based coatings. They can make the coating look uneven. Sometimes, spots do not cure right. This can cause weak or bad areas in your finish.

Photoinitiator 819 DW mixes well in water-based coatings. It spreads out evenly and does not clump. You see fewer problems and get a smooth finish. Your coatings dry faster and cure better.

- Conventional photoinitiators: Do not work well with water-based coatings. This can cause uneven mixing and problems.

- New water-based photoinitiator: Mixes better, spreads out easily, and cures faster.

You can use this photoinitiator for green projects. It helps you follow eco-friendly rules and use fewer harmful chemicals.

Versatile with Different Chemistries

You need a photoinitiator that works with many resins. Photoinitiator 819 DW fits into many types of coatings. You can use it in adhesives, composites, and special coatings. It works with both old and new resin systems.

The photocrosslinking of polymer blends used UV light and Photoinitiator 819 DW (BAPO, IRGACURE 819™). The study showed how to make a BAPO solution and add it to polymer blends. This shows it works in adhesives and composites.

You can trust this photoinitiator for special jobs. It works in coatings for wood, plastic, textiles, and paper. You get strong finishes and good curing every time.

Here is a table showing where you can use Photoinitiator 819 DW:

| Toepassingsgebied | Compatible? | Voordeel |

|---|---|---|

| Coatings op waterbasis | Ja | Smooth, even cure |

| Lijmen | Ja | Strong bonding |

| Composites | Ja | Deep, full cure |

| Specialty coatings | Ja | Versatile performance |

You can pick this photoinitiator for many projects. It helps you get good results, no matter what system you use.

5. Low Migration and Safety

Minimal Migration Risk

You want coatings that are safe and work well. Fotoinitiator 819 DW helps keep migration very low. Migration is when chemicals move from the coating to other things. This can be a problem for food packaging or toys.

Photoinitiator 819 DW stays in the coating. It does not move into food, skin, or other surfaces. You can feel safe using it for sensitive products.

Here are some reasons why low migration is important:

- Keeps food packaging safe 🍎

- Protects children’s toys and books

- Lowers risk for medical devices

Tip: Low migration helps stop recalls and complaints. You can trust your products to be safe.

Look at the table to see how Photoinitiator 819 DW compares to others:

| Toepassingsgebied | Standard Photoinitiator | Fotoinitiator 819 DW |

|---|---|---|

| Voedselverpakking | Medium Migration | Very Low Migration |

| Children’s Products | Medium Migration | Very Low Migration |

| Medische apparaten | Medium Migration | Very Low Migration |

Supports Regulatory Compliance

You must follow rules for coatings, especially for food, toys, and healthcare. Photoinitiator 819 DW helps you meet these rules. It supports many safety standards worldwide.

You can use this photoinitiator to:

- Meet FDA and EU food contact rules

- Pass toy safety tests

- Follow REACH and other chemical laws

Opmerking: Using a compliant photoinitiator makes your work easier. You spend less time on paperwork and testing.

You can feel sure your coatings will pass checks. Customers and inspectors will trust your products. Photoinitiator 819 DW gives you a safer and smarter choice for coatings today.

You get many advantages when you choose Photoinitiator 819 DW for coatings:

- You see fast curing and bright, stable colors.

- You can use it in UV-WPUA resins, self-wrinkled polymer films, and LED chip coatings.

- You help the environment with low odor and low volatility.

The most cited benefits include:

- Weinig vergeling under UV light.

- Deep cure for thick coatings.

- High activity and good solubility.

You make your coatings safer and easier to approve for many uses.

FAQ

1. What makes Photoinitiator 819 DW different from other photoinitiators?

Fotoinitiator 819 DW cures coatings much faster. It keeps colors looking bright for longer. It also cures thick coatings all the way through. It works well in water-based and colored coatings. You will notice less yellowing as time goes by.

2. Can you use Photoinitiator 819 DW in food packaging?

Yes, you can use it for food packaging. Photoinitiator 819 DW does not move out of the coating much. This helps you follow food safety rules. It is safe for coatings on food packages and kids’ products.

3. Does Photoinitiator 819 DW work with LED curing?

You can use Photoinitiator 819 DW with LED lights. It cures coatings fast under LED light. You get a strong and even finish every time.

4. Is Photoinitiator 819 DW safe for the environment?

Photoinitiator 819 DW is better for the environment. It works in water-based coatings and does not smell much. You use fewer chemicals that can harm nature.